Drawer and Housing magnet is the perfect aid in removing stray tramp metal. The drawer magnet assembly is much suited for free flowing dry materials. The design of Magnetic drawer is so that it traps every ironers material coming into contact with the magnetic grate. As the housing magnet is directly fitted into the process line, body is made completely in SS which matches all food standard norms. The product is available in three different models to suite the extensive use in varied manufacturing areas.

The drawer and housing magnet is referred in many different names like drawer in housing magnet, drawer magnet, magnetic drawer, housing magnet, magnetic grate and grate magnets. Star Trace Solutions Pvt. Ltd. located in Chennai, Tamilnadu, India is a pioneer in manufacturing magnetic grate. Their rich experience in the field of magnetism as manufacturers, suppliers and exporters has had hovering sales all through the years. Quality, prompt delivery and custom made solutions are the key features which lead to our success as leading manufacturers, suppliers and exporters. Established in Chennai, Tamilnadu, India all our equipments are MADE IN INDIA.

By constantly updating and revising technology according to market trends we have come out with three uniquely designed for of drawer and Housing magnet. Necessity, kind of separation and budgeting are the few factors that influence the customer in deciding the model for sales.

In the construction needing physical operation the built up is the same where as removing of the drawer magnet has to be done by a person. This has to be done with care as sharp items may be stuck to the grate. Using gloves or handling with cloth is advised. This kind of magnetic grates can be installed where it can be easily installed & operated. Sales of these are recommended where labour is never a problem.

SPECIFICATIONStar Trace's Exposed Pole plate Magnets are engineered to deliver high performance tramp metal separation in low volume applications. These applications are for below-the flow installations where the product flows over the plate magnets face.

| Model | GRATE SIZE AX B | Banks | Tubes | C | Cu. Ft/ Hr. | Bulk Density(Ibs./Cu.ft.) Pounds Per Hour |

Weights Kgs | |||

| 40 | 50 | 60 | 70 | |||||||

STR0606_2 STR0606_3 STR0606_4 |

150 150 150 |

2 3 4 |

5 8 10 |

205 208 355 |

450 338 338 |

18000 13520 13520 |

22500 16900 16900 |

27000 20280 20280 |

31500 23660 23660 |

8.164 10.886 13.154 |

STR0608_2 STR0608_3 STR0608_4 |

205 205 205 |

2 3 4 |

7 11 14 |

205 208 355 |

800 600 600 |

32000 24000 24000 |

40000 30000 30000 |

48000 36000 36000 |

56000 42000 42000 |

11.339 15.422 19.050 |

STR1010_2 STR1010_3 STR1010_4 |

255 255 255 |

2 3 4 |

9 14 18 |

205 208 355 |

1250 938 938 |

50000 37520 37520 |

62500 46900 46900 |

75000 56280 56280 |

87500 65660 65660 |

16.782 22.679 28.122 |

STR1212_2 STR1212_3 STR1212_4 |

305 305 305 |

2 3 4 |

11 17 22 |

205 208 355 |

1800 1350 1350 |

72000 54000 54000 |

90000 67500 67500 |

108000 81000 81000 |

126000 94500 94500 |

20.411 28.576 35.380 |

STR1414_2 STR1414_3 STR1414_4 |

355 355 355 |

2 3 4 |

13 20 26 |

205 208 355 |

2450 1838 1838 |

98000 73520 73520 |

122500 91900 91900 |

147000 110280 110280 |

171500 128660 128660 |

26.761 37.194 47.173 |

STR1616_2 STR1616_3 STR1616_4 |

405 405 405 |

2 3 4 |

15 23 30 |

205 208 355 |

3200 2400 2400 |

128000 96000 96000 |

160000 120000 120000 |

192000 144000 144000 |

224000 168000 168000 |

33.565 47.173 59.420 |

STR1818_2 STR1818_3 STR1818_4 |

455 455 455 |

2 3 4 |

17 26 34 |

205 205 355 |

4050 3038 3038 |

162000 121520 121520 |

202500 151900 151900 |

243500 182280 182280 |

283500 212600 212600 |

40.823 57.606 73.028 |

STR2020_2 STR2020_3 STR2020_4 |

508 508 508 |

2 3 4 |

19 29 38 |

205 208 355 |

5000 3750 3750 |

200000 150000 150000 |

250000 187500 187500 |

300000 225000 225000 |

350000 262500 262500 |

48.354 68.946 87.996 |

STR2222_2 STR2222_3 STR2222_4 |

560 560 560 |

2 3 4 |

21 32 42 |

205 208 355 |

6050 4538 4538 |

242000 181520 181520 |

302500 226900 226900 |

363000 272000 272000 |

423500 317660 317660 |

57.152 81.646 104.326 |

STR2224_2 STR2224_3 STR2224_4 |

610 610 610 |

2 3 4 |

23 35 46 |

205 208 355 |

7200 5400 5400 |

288000 216000 216000 |

360000 270000 270000 |

432000 324000 324000 |

504000 378000 378000 |

66.224 95.254 122.016 |

A fully automated working is planned with touch of a button so there is no time spent in manual work. Sales of automatic machines are recommended where the drawer magnet has to be fixed in unreachable places as well as in progress lines which cannot afford to waste instances and high productivity is aimed.

We have presented to you variations in housing magnet for which we are manufacturers, suppliers and exporters. Stationed in Chennai, Tamilnadu, India we are the leaders in sales for almost all the magnetic equipments. Take advantage of our expertise and we are sure to improve your output.

| Model | mm | mm | mm | mm | Number of Tubes | Number of Banks | Number of Drawers | Cu.Ft/ Hr. | Bulk Density (Ibs./ Cu. ft.) Pounds Per Hour |

Weights Kgs. | |||

| 40 | 50 | 60 | 70 | ||||||||||

STR0606_2SC STR0606_3SC STR0606_4SC |

150 150 150 |

360 360 360 |

200 250 300 |

300 300 300 |

5 8 10 |

2 3 4 |

1 1 1 |

12 9 9 |

8100 6080 6080 |

10125 7605 7605 |

12150 9125 9125 |

14175 10645 10645 |

41 50 58 |

STR0808_2SC STR0808_3SC STR0808_4SC |

200 200 200 |

410 410 410 |

200 250 300 |

350 350 350 |

7 11 14 |

2 3 4 |

1 1 1 |

22 16 16 |

14400 10800 10800 |

18000 13500 13500 |

21600 16200 16200 |

25200 18900 18900 |

49 62 73 |

STR1010_2SC STR1010_3SC STR1010_4SC |

250 250 250 |

460 460 460 |

200 250 340 |

400 400 400 |

9 14 18 |

2 3 4 |

1 1 2 |

34 25 25 |

22500 16880 16880 |

26125 21100 21100 |

33750 25325 25325 |

39375 29545 29545 |

58 74 108 |

STR1212_2SC STR1212_3SC STR1212_4SC |

300 300 300 |

510 510 510 |

200 300 340 |

450 450 450 |

11 17 22 |

2 3 4 |

1 2 2 |

49 36 36 |

32400 24300 24300 |

40500 30375 30375 |

48600 36450 36450 |

56700 42525 42525 |

68 89 128 |

| STR1414_2SC | 350 | 560 | 200 | 500 | 13 | 2 | 1 | 66 | 44100 | 55125 | 66158 | 77175 | 80 |

| STR1616_2SC | 400 | 610 | 200 | 550 | 15 | 2 | 1 | 86 | 57600 | 72000 | 86400 | 100800 | 92 |

| STR1818_2SC | 450 | 665 | 200 | 600 | 17 | 2 | 1 | 109 | 72900 | 91125 | 109575 | 127575 | 105 |

| STR2020_2SC | 500 | 715 | 250 | 650 | 19 | 2 | 2 | 135 | 90000 | 112500 | 135000 | 157500 | 119 |

| STR2222_2SC | 550 | 765 | 250 | 700 | 21 | 2 | 2 | 163 | 108900 | 136125 | 163350 | 190575 | 134 |

| STR2424_2SC | 600 | 815 | 250 | 750 | 23 | 2 | 2 | 194 | 129600 | 163800 | 194400 | 226800 | 150 |

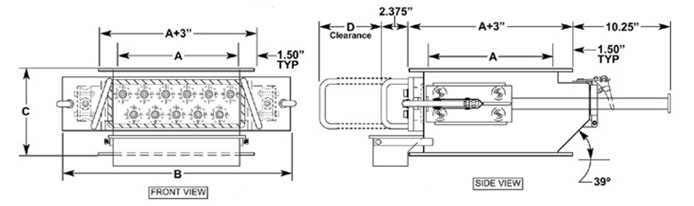

These models are easy to eliminate the stuck substance on the magnet. When the operator pulls the magnetic drawer they pass through a scraper individually, in the course removal happens and is collected in the tray below.By using this time is saved to a large extent and is safe as well.

| Model | mm | mm | mm | mm | Number of Tubes | Number of Banks | Number of Drawers | Cu.Ft/Hr. | Bulk Density (Ibs./ Cu. ft.) Pounds Per Hour | Weights Kgs | |||

| 40 | 50 | 60 | 70 | ||||||||||

STR0606_2EZ STR0606_3EZ STR0606_4EZ |

150 150 150 |

380 380 380 |

200 250 300 |

280 280 280 |

5 8 10 |

2 3 4 |

1 1 1 |

450 338 338 |

18000 13520 13520 |

22500 16900 16900 |

27000 20280 20280 |

31500 23660 23660 |

26 35 42 |

STR0808_2EZ STR0808_3EZ STR0808_4EZ |

200 200 200 |

430 430 430 |

200 250 300 |

330 330 330 |

7 11 14 |

2 3 4 |

1 1 1 |

800 600 600 |

32000 24000 24000 |

40000 30000 30000 |

48000 36000 36000 |

56000 42000 42000 |

32 44 55 |

STR1010_2EZ STR1010_3EZ STR1010_4EZ |

250 250 250 |

480 480 480 |

200 250 340 |

380 380 380 |

9 14 18 |

2 3 4 |

1 2 2 |

1250 938 938 |

50000 37520 37520 |

62500 48900 46900 |

75000 56280 56280 |

87500 85660 65660 |

40 55 77 |

STR1212_2EZ STR1212_3EZ STR1212_4EZ |

300 300 300 |

530 530 530 |

200 300 340 |

430 430 430 |

11 17 22 |

2 3 4 |

1 2 2 |

1800 1350 1350 |

72000 54000 54000 |

90000 67500 67500 |

108000 81000 81000 |

126000 94500 94500 |

48 68 95 |

STR1414_2EZ STR1616_2EZ |

350 400 |

580 630 |

200 200 |

480 530 |

13 15 |

2 2 |

1 1 |

2450 3200 |

96000 128000 |

122500 160000 |

147500 192000 |

171500 224000 |

57 68 |

Devoted to manufacturing magnetic equipment for the past 25 years Star Trace has perfected every machine it manufacturers in terms of functioning, technology and durability. Drawer and housing magnet is one among them involved in capturing ferrous contaminants which may cause damage to other parts of the machinery as well as decrease the quality of the output.

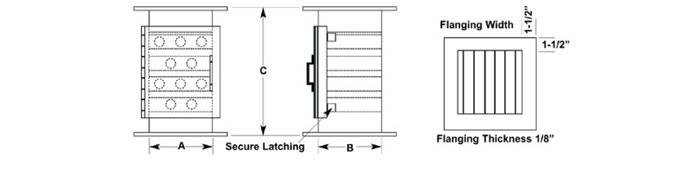

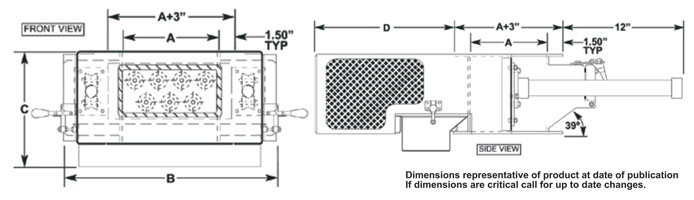

The construction of drawer and housing magnet consist of horizontal magnetic tubes arranged in alternating manner to make contact with every grain entering the drawer magnet. This ensures effective removal of all possible ferrous contaminants. Cleaning the housing magnet can be done either manually or automatically. Three variants are available based on the mode of cleaning,

It would be a wise decision to go for self-cleaning models if the place of installation is not easily accessible. Few manufacturers who use the Drawer and Housing Magnet are food grains, sugar, pharmaceutical, cement, gypsum etc.

Star Trace being one of the big names in the magnet manufacturing segment has a long list of magnetic separation equipment. The Drawer-in- Housing magnet is a compact machinery for trapping ferrous material from free flowing dry input. When the input is fed into the housing they come into contact with stacked rows of magnetic rods. The placement of magnetic rods are such that the fall of feed is crisscross to have maximum contact. By maximizing contact efficiency is increased. Removing the ferrous particles can be done manually or by employing self-cleaning or EZ clean models. Remarkable features of Drawer-in-Housing Magnet are,

Industries that make use of Drawer-in-Housing magnet are pharmaceutical, industries, gypsum, industries dealing with powdery substances, food processing industry etc.

Drawer Magnets are also called Drawer-in-House magnets. These magnets are used for refining the input of iron impurities. The impurities would have entered the stream along with input as contaminants or as a result of withering of working parts. There are 3 variations in Drawer Magnets; classified on the method of cleaning, they are,

In manual cleaning method the magnetic rods are cleaned with the help of a cloth. The other EZ clean drawer-in-housing are fitted with a mechanism of self-cleaning when the drawer is pulled out and collected in a trey below. The Self-cleaning drawer in housing works with a touch of a button. It is sensible to use the automatic type in areas were access is difficult.

Applications of Drawer MagnetThe perfect mechanism developed by Star Trace to trap iron impurities in dry inputs is the Magnetic Drawer. The equipment is designed like a housing which has horizontal magnetic rods in the flow of input. The arrangement of rods in rows are in an alternating pattern to ensure that all inputs entered comes into contact with the rod to trap impurities. Multiple rows of rods can also be increased, if the clients demands. Regular shapes are square and circular however other shapes can be custom made depending on requirement. As the magnetic drawer is to be installed at the feeding point or at the discharging end not much changes need to be done for introducing it.

Industries using magnetic Drawers include:Magnetic Drawer manufactured by Star Trace are known for their precise working quality and durability. Experience or expertise.

Star Trace being the leading manufacturer of Housing Magnet has supplied hundreds of them to clients in India and abroad. The housing magnet has the following features:

The cleaning mechanism is available in three types

In manual cleaning a person has to remove the magnetic rods wearing gloves with a cloth. This suites places where they are approachable and labor is available.

EZ Clean gives way to cleaning the magnetic rods when pulled out of their housing. The removed tramp iron is collected in the tray below. This method of cleaning does not consume time.

Self-Cleaning is a fully automated cleaning method which just needs the click of a button.

The Magnetic Grate also known as the Drawer and Housing magnet is a must have for all industries which handle dry feeds. Ferrous impurities present in the input will be trapped by the magnetic grate which can be cleaned manually or automatically. The magnetic rods are arranged in an alternating manner to make maximum contact with the feeds. Increasing contact will improve the working efficiency of magnetic grate. If high levels of contaminants are expected the number of magnetic rows in the grate can be increased. Regular shapes designed are round and square, customized shapes are also delivered against order.

Pharmaceutical, fertilizer, food grain, cement, gypsum, and all industries handling dry inputs have magnetic grates working for them. The Grate magnet has the most convenient way of installation i.e is at the hopper end or at the discharge end of pulverizers, blenders or any equipment. Magnetic grates are sure to improve your product quality.

Star Trace is one of the big names in magnetic equipment manufacturing. With over two and a half decades of experience in manufacturing; our products are given preference over the others for their quality, durability and cost effectiveness. Grate Magnets are remarkable in removing ferrous impurities of all kinds. Cleaning the magnetic rods are either manual, Self-cleaning (automatic) or EZ cleaning (semi- automatic).

Grate magnets are fitted at the hopper end where the feed is introduced. Magnetic rods are arranged in horizontal rows disrupting the flow of raw material, this is when the actual trapping of impurities take place. Cleaning the rods of impurities is done either,

Choosing the cleaning method can be decided by availability of labor, accessibility to the Grate magnet installation area and expected output rate. Star Trace’s grate magnets are very efficient in working beyond expectations install them to achieve exceptional results.