Liquid Line Magnetic Separators are exquisitely designed magnetic separators to remove tramp iron from any liquid stream. During the production process there are chances that very fine iron particles mix up in the product stream and bring down the quality of the end product. There are situations where in they go unnoticed by metal detector and are not affordable by manufacturers, suppliers and exporters as the output will lose its quality.

In such situations Liquid Line Magnetic Separators play a vital role and remove the fine contaminants and step up standards. The Liquid Line Magnetic Separators are capable of handling liquids of varying consistencies from water to sauce. Though the differences in consistencies have an impact on effectiveness, the Liquid Line Magnetic Separator models and variations aptly suite them and fill gaps to bringing maximum effectiveness.

Star Trace head quartered in Chennai, Tamilnadu, India has twenty five years of experience and s have developed equipment that work effectively in magnetic separation. All the products including the Liquid Line Magnetic Separator are subjected to continuous upgradation as different techniques emerge. Being a leading manufacturer, supplier and exporter of a wide array of machines we have also topped sales.

The Liquid Line Magnetic Separator is also referred by other names like Inline Magnetic separator, Liquid Line Magnetic Traps and Liquid Line Separator.

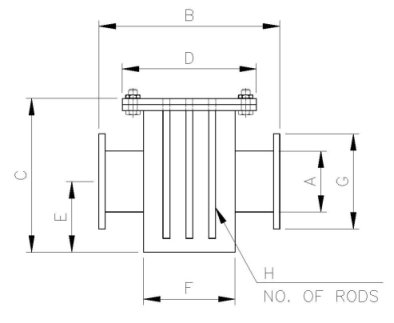

The Liquid Line Magnetic Separator has a lid arrangement on which the magnetic rods are fixed when fitted into the process line they cut across the flow of liquid. This arrangement of the Liquid Line Magnetic Separator keeps contact with the entire flow of liquid and makes it easier to trap fine iron impurities. Varying specifications of Liquid Line Magnetic Separator are available and can either be positioned horizontally or vertically or even at a slope. The Liquid Line Magnetic Separator is designed in such a way that their performance is not affected by their positioning.

Prominent features of Liquid Line Magnetic Separator:

Cage design T traps:

The Liquid Line Magnetic Separators are available in ‘T’ shaped design to handle large volumes and semi liquids. The magnetic rods of the Liquid Line Magnetic Separator hold back ferrous contaminants that flow through the magnetic field. Once considerable amount of iron particles have collected the Liquid Line Magnetic Separator can be unscrewed and cleaned for resuming to work.

Plate T Traps:

To deal with feeds of viscous and fibrous consistencies the Plate T trap type Liquid Line Magnetic Separator is used. They are the perfect combination for complete removal of ferrous impurities. Standard sizes are readily available for sale where as special dimensions are made to order after the sales request has been placed. As one of the leading manufacturers, suppliers and exporters from Chennai (Tamilnadu, India) we strive to meet the request of all our clients present globally.

Liquid Line Magnetic Separators are a mandate in liquid handling assemblies as they are the best option to rule out iron contaminants. Star Trace offers a series of Liquid Line Magnetic Separators to meet the growing demands of diverse industries. Possible entry of ferrous contaminants is through raw materials and at times due to wear and tear of machinery. Entry of impurities is inevitable and necessary steps like installing the Liquid Line Magnetic Separator has to be taken to improve the quality of the product and to protect other parts of machinery from damage.

The Liquid Line Magnetic Separator has a chamber like appearance with inlet and outlet openings. The magnetic rods of the Liquid Line Magnetic Separator are fitted in the lid which when screwed in position will pass right through the liquid stream.

Outstanding features of Liquid Line Magnetic Separator:

Star Trace, a pioneer in manufacturing magnetic equipment has designed the Liquid Line Magnetic Separator which is capable of handling liquids of different densities to purify them of ferrous impurities. As a leading manufacturer we come up with superior products that exhibit outstanding performance to meet the requirements of clients. Tubes fitted with strong magnets protrude into the liquid stream and trap ferrous impurities. On screwing open the lid of the Liquid Line Magnetic Separator collected impurities can be removed. Available in standard Manufacturers of the Liquid Line Magnetic Separator can also be customized to match the require. Few of the manufacturers using the Liquid Line Magnetic Separator are:

The Liquid Line Magnetic Separator is constructed using high grade Stainless Steel which is safe for food handling industry and at the same time they are easy to maintain. Drop in an enquiry to know more.

Experience yet another superior product from Star Trace which as with stood the test of time and excelled as leader in sales. Of the many equipment manufactured Inline Magnetic Separator is a simple yet effective way of separating ferrous contaminants from liquids, which is a tough job indeed. The arrangement of magnetic rods are vertical and can be dipped directly into the flowing liquid line in a cage like preparation through which the liquid flows. Separation of tramp iron starts once the liquid is released through the Inline Magnetic Separator. Cleaning the rods of tramp iron is simple and can be put back to work immediately.

Significant Features of Inline magnetic separator:

Liquid Line Magnetic Separators designed by Star Trace are standing examples of perfection. The rare earth magnetic rods arranged vertically on the lid attract to itself irony material freely floating in the liquid. These impurities may have arrived along with raw materials or as parts of the assembly line withering. Whatever the source may be its important to remove them to improve the quality of output or end product. Installing a Liquid Line Magnetic Separator is the best possible way to get rid of them. To introduce it no major changes need to be done if it is to be introduced into an existing assembly. Perfect fitting arrangements are available to make the line leak proof. If a custom made arrangement is required Star Trace has everything in place and can be delivered to your requirements. A few of the industries which have put Liquid Line Magnetic Separators to use are paint, pigment, syrup, sauce, juice, pulp etc.

Technical Data of Cage Style Magnet:

Technical Data of Cage Style Magnet:

| CAGE STYLE | |||||||||||||

| ALL DIMENSION ARE IN INCHES | Litres/Min |

||||||||||||

| Part No | A | B | C | D | E | F | G | H | Group1 | Group 2 | Group 3 | Group 4 | Weight Kg |

| STR 02 | 2 | 10 | 6 | 7.5 | 3.25 | 7.5 | -9 | 5 | 546 | 382 | 191 | 82 | 13.2 |

| STR 02.5 | 2.5 | 12 | 7.5 | 9.75 | 4.38 | 9.75 | 0 | 7 | 909 | 638 | 318 | 136 | 22.7 |

| STR 03 | 3 | 12 | 9 | 9.75 | 4.38 | 9.75 | 0 | 7 | 909 | 636 | 318 | 136 | 22.7 |

| STR 04 | 4 | 12 | 12 | 10.25 | 4.38 | 9.75 | 0 | 7 | 1227 | 859 | 432 | 186 | 27.2 |

| STR 06 | 6 | 23 | 18 | 16 | 13.38 | 10.75 | 11 | 9 | 7273 | 5091 | 2545 | 1236 | 104.4 |

| STR 08 | 8 | 26 | 24 | 19 | 17.25 | 12.75 | 13.5 | 9 | 7273 | 5091 | 2545 | 1236 | 124.7 |

| STR 10 | 10 | 30 | 30 | 23.5 | 21 | 16 | 16 | 15 | 7273 | 5091 | 2545 | 1236 | 261 |

| STR 12 | 12 | 34 | 36 | 25 | 21 | 18 | 19 | 15 | 14318 | 10023 | 500 | 2432 | 295 |

| STR 14 | 14 | 36 | 42 | 27.5 | 23.38 | 20 | 21 | 15 | 14371 | 10023 | 500 | 2432 | 333.5 |

| STR 16 | 16 | 40 | 46 | 32 | 25.63 | 24 | 23.5 | 17 | 23836 | 18545 | 8273 | 4000 | 442.4 |

| STR 18 | 18 | 40 | 50 | 32 | 27.5 | 24 | 25 | 17 | 23836 | 16545 | 8273 | 4000 | 476.4 |

| PLATE STYLE | |||||||||

| Model no. | A | B | C | D | Group1 | Group 2 | Group 3 | Group 4 | Weight Kg |

| STR-15 | 1.5" | 4.25" | 5.50" | 10.0" | 245 | 189 | 94 | 57 | 8 |

| STR-20 | 2.0" | 4.25" | 5.50" | 10.0" | 245 | 189 | 94 | 57 | 8 |

| STR-25 | 2.5" | 4.75" | 7.75" | 13.5" | 528 | 339 | 226 | 132 | 14 |

| STR-30 | 3.0" | 4.75" | 7.75" | 13.5" | 528 | 339 | 226 | 132 | 14 |