The overband magnetic separators are designed to handle high volumes in the most rugged conditions.Overband magnets are very common in mining plants, which are made to toil round the clock, so is their use and demand. Magnetic separators are put to use in many industries where the product needs to be devoid of iron. In areas with very heavy inputs; combination of overband magnetic separators and another equipment using powerful magnet may be used which ensures to pull up every single granule.

We, Star Trace Solutions Pvt. Ltd. Chennai, Tamilnadu, India have been in the magnet business for nearly three decenniums which has given us lot of opportunity to perfect our selves. Having grabbed all the prospects we are leaders in sales and established manufacturers, suppliers and exporters not only in Chennai, Tamilnadu, India but globally.

How does the Overband magnetic separators function?

The Overband magnetic separators use the magnetic property of permanent or electro magnet to separate all ferrous containing bodies. The overband has two pulleys which are covered by a belt that moves when the pulley is initiated for movement. A forceful magnet is stationed between them to attract materials that pass through the magnetic field. When the belt moves away from the magnet upon rotating, particle stuck to it are released into a separate collection area.The whole set up of overband magnetic separators are suspended from above by four sturdy chains.

Significance of Overband Magnetic Separator:

Industries using Magnetic Separator such as overhead magnetic separators are

The overband magnetic separators are being used by small, medium and large manufacturers depending on the purpose that needs to be served. The self cleaning overband model Magnetic Separator sales are usually seen in larger volume handling where as manual collection overband sales in lofty small enterprises. If you are inexperienced in finding the apt magnetic separation method we are there to help you. With years of experience as manufacturers, suppliers and exporters you can rely on us for expert opinion. We as suppliers and exporters always go by the principles of quality, trust, keeping words, customer centric, on time delivery and last but not the least long lasting relationship.

Contact our well informed sales team to discuss your requirements on Magnetic Separator or you can e-mail us regarding specification and get a quote which will help you to move forward in achieving your goal. Lets join hands to bring out an efficient, cost effective and technically advanced project. Looking forward to hear from you.

STAR TRACE Magnetic Roll Separators are roll type dry magnetic separators with fixed magnet having high field intensity and gradient. The magnets used in the Roller Magnetic Separators and made of alloys of rare earth elements are more powerful as compared to other magnets. They generate high attraction forces on the magnetic roller due to their properties and special magnetic series. The obtained high magnetic attraction forces have low magnetic sensitivity and therefore they make it possible to separate very fine low magnetic minerals with a high recovery.

The most distinguishing property of Magnetic Roll Separators as Magnetic Separator is, the magnets are an alloy of rare earth elements produced domestically and more powerful. Magnetic Separator System has a number of standard sizes in which the high gradient separators are produced, and all of these sizes only require a low installation height. It is also possible to make a system in accordance with customer specifications. Depending on the requirements made and the application for Magnetic Separator, a choice can be made for a single stage system or for multiple magnet rollers under one another. This results in an even higher degree of iron separation.

Our latest developments in higher gauss value with star ultra super rare earth magnets with highest intensity,high gradient magnet arrangement in special proprietary configurations are now available after extensive research and development.

STAR TRACE is one of the Asia's leading manufacturing Company in Permanent Magnetic Equipments and Vibrating Equipments in Dry/Wet Separation of minerals and metals. The Dry Permanent Magnetic Roll Separators systems are unique in nature and we are supplying similar Magnetic Separator equipment throughout the world and more than 1000 Industries are having our Equipments. In our past 25 years of experience, with our Magnetic Separator we can separate from Coal to Gold in all minerals and metals from anywhere in the world, depending upon on their mining location, we are able to provide you complete solutions to upgrade your metals, minerals and your processes.

These Magnetic Roll Separators are highly effective of separating para magnetic particles and weakly para magnetic particles separately. These Rare Earth Magnetic Separators are made up of very high power specially developed Nickel, Iron Boron (Nd-Fe-B) with highest magnetic power available in the series to enable us to achieve very high gauss value compared to other similar products.

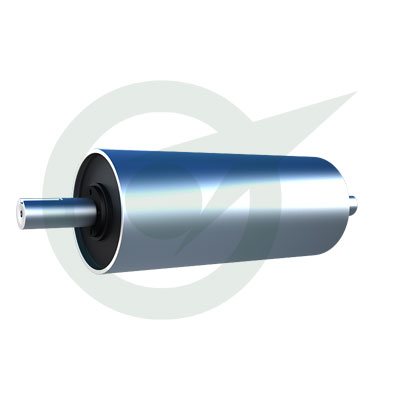

Right now in the series of Magnetic Separator we have developed latest Magnetic Roll Separators with a diameter of 150mm which gives higher magnetic force and more contact area than the normal 100mm diameter magnetic rollers. These Magnetic Rollers are specially configured with configurations of suitable material sizes and its magnetic properties. The Magnetic Roll Separators have been passing through belt which is made of different materials with different thickness to suit effective beneficiation of separating minerals and metals.

These effective magnetic roll separators can be achieved with different thickness of belt ranging from 0.25mm to 2mm and some of the belt material which we have been using are having a non stick property and they are highly resistant to abrasiveness. Some of the belt material are coated with Nylon for its non stick property. These belts are basically made up of Kevlar, which is a Bullet Proof material and highest strength of its kind. These STAR TRACE Magnetic Roll Separators are having several passes to make sure of highest purity can be obtained by which several process repeatedly without much material handling. These Magnetic Roll Separators are primarily used in replacement of old technology of induced magnetic roll separators.

Magnetic Roll Separators Working Principle:

Magnetic Roll Separators consist of two rolls, one of which is magnetics. There is a belt between them to carry the ore into the magnetic field. The movement of the belt is controlled by a motor fixed to one of the rollers. The rotational speed of the Magnetic Separator rollers can be adjusted according to the material properties.

The material to be processed is conveyed to the belt by vibrating feeder at a required rate to the Magnetic Separator. Feeding rate can be controlled by adjusting the vibration on feeder. Roll separators blade has been set in order to be able to collect separated products in different places and to adjust the product properties in a desired manner.

Magnetic Roll Separators Technical Features:

Magnetic Roll Separators Construction:

The magnetic rollers incorporated in our machines have been specially designed and developed to generate exceptionally high magnetic field and gradient and serve as Magnetic Separator. The magnetic rollers which are built using rare earth Nd-Fe-B are manufactured to very low dimensional tolerances. The magnetic rollers incorporated in our machines have been specially designed and developed to generate exceptionally high magnetic field and gradient. The magnetic rollers which are built using rare earth Nd-Fe-B is manufactured to very low dimensional tolerances.

Star Trace India is an exporter, manufacturer & supplier concerning Magnetic Separators, magnetic drum separator & various other equipments which utilize the magnetic property pertaining magnets. Permanent drum design magnetic separator ensures purity of end product, metal extraction that have sale value, preventing other machinery from damage, resulting magnetic activity. As manufacturers, suppliers & exporters we design magnetic roll separator along single, double & triple drum. Multiple drum design was introduced matching all manufacturers, suppliers & exporters who need magnetic separation towards improved sale. It has been a proven technique to use permanent magnet design drum facilitating removal regarding ferrous impurities.

Magnetic drum separator design Feeder:

Place from where the feed be introduced, has vibratory motion: making even spreading possible.

Magnetic drum:

Though the drum attracts iron particles, it does not have magnetic properties. A semicircular permanent magnet lodged within the drum radiated magnetic field. Half drum area exhibits magnetic field & remaining half does not. Electro magnets may be used on sale request relating client's specific area. Manufacturers & suppliers dealing other products also use the drum design facilitating smooth functioning. Exporters give due priority towards drum numbers in Magnetic Separator.

Collection:

Collecting, iron as well as non ferrous material happens at collection point in two separate places. The drum attracts towards itself ferrous feed & non ferrous deflects towards another area. Drum number varies in different sale; depending on number of times refining is needed. When fine clarified output is needed by manufacturers drum number up to three, customizing drum number & design may vary towards satisfy all sale parameters.

Magnet Drum Separator Construction:

Drum separator is a very common Magnetic Separator in any mining industry. There are two types of magnetic drum separators, one, dry permanent magnetic drum separator and second wet drum magnetic separator. The drum magnetic separator handles wet inputs from which magnetic material have to be separated. There are many names by which it is called they are Wet Drum Permanent Separators,Wet Drum Magnetic Separators,Wet Drum Separators,Low Intensity Magnetic Separator (LIMS) & Wet Magnetic Drum. The main aim of the magnetic separator is to recover the maximum amount of ferrous by using the intensity of the permanent magnet. Our drum separator is fitted with high intensity magnets which effectively carry out the separation process.

Working:

The magnetic separator assembly has fixed magnet inside the rotating drum. When the liquid input is fed into the low intensity magnetic separator (LIMS) all particles which are ferrous in nature, even the low intensity elements are attracted by permanent magnet which is placed within the drum and carried along with the rotating drum to be separated from the main stream. The rest of the liquid with particles showing no attraction to the intensity of the magnet are disposed out through separate exit point.

Star Trace located in Chennai, Tamilnadu, India is a pioneer among manufacturers, suppliers & exporters of magnetic pulley. The sales of magnetic pulley has steady movement amid stiff competition, we owe this to stringent quality checking measures & constant up-gradation. With continuous improvements in standards we are globally known, manufacturers, suppliers & exporters & leaders in sales as well.

Magnetic head pulley is one of the widely used equipments in magnetic segregation. Segregation using magnetic pulley head is seen in industries where magnetic materials have to be removed from non magnetic input. The purpose of magnetic pulley as a Magnetic Separator in food processing industry is to separate any ferrous substances like iron fillings or pins which would have fallen by mistake. By removing magnetic contaminants, foodstuff is safe for consumption.On the other hand remaining elements of the machinery are also protected. Similarly magnetic pulley head is very advantageous in many fields. Use of magnetic pulley is sure to improve sales indirectly.

Construction of magnetic head pulley:

Magnetic Head pulley has uncomplicated set up and operation. Parts involved are magnetic pulley as head,conveyor belt, permanent magnet & diverter. Substance to be treated is fed on the conveyor, as the conveyor moves it reaches the magnetic pulley head. On contact with rotating magnetic pulley all irony matter stick to the conveyor where as non irony ones fall off the conveyor. Ironies stuck to conveyor move along it till they are released from magnetic field. A separator positioned below permanent magnet pulley head segregates the two types of output.

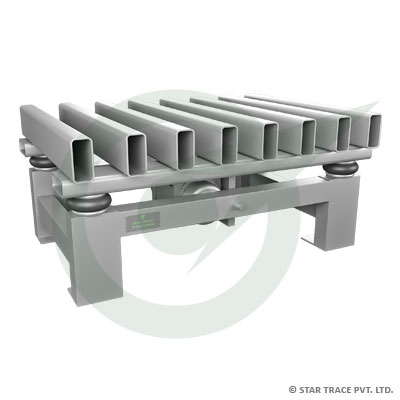

The magnetic grill which is one of the prominent Magnetic Separator has become the default products in all manufacturing units, handling dry feeds. The use of grill magnet as Magnetic Separator is so incredible that it is considered wise to install it in the very beginning. The magnetic grill works with dedication in trapping all ferrous particles passing through it. By doing so impurities are removed at this stage and other parts through which the input passes is protected from damage, facilitating smooth work flow. Star Trace has been into the business of magnets for not less than twenty five years and is one of the leading manufacturers, suppliers and exporters with remarkable sales in all segments of magnetic machinery.

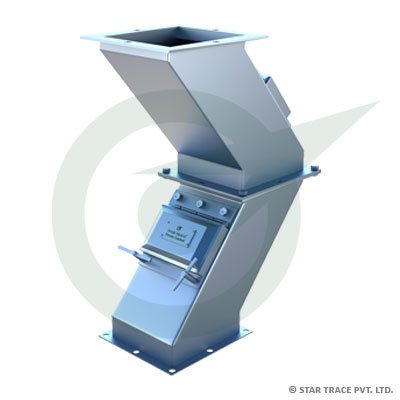

The grill magnet is designed in such a way that it fits almost all the hoppers as Magnetic Separator and would not require any customization, but still for the convenience of our clients we do customize in accordance with the existing hopper. Let’s look into the making of a grill magnet.

The magnetic grill consists of tubes which are fitted with magnets inside. These are placed one beside the other, with a calculated amount of space to facilitate efficient working. The paralleled cylinders are held in place by holders, running transversely. The entire magnetic grill is made of stainless steel and is usually round or rectangular in shape. Other shapes can also be catered, upon receiving specifications. Positioning of themagnetic grill is usually at the hopper. But in some manufacturing units hopper may not be suitable or accessible, in such cases placing them at collection point or at catch bins will serve the purpose.

How the magnetic grill is put to use. The magnetic grill is placed on the hopper and the feed to be refined of contaminants is fed into the hopper, upon coming into contact with magnetic field of the grill magnet, all particles which are ferrous in nature stick to the grill and the rest flow freely. Hoppers are also fitted with double magnetic grill which will further restrict the passage of iron substances. Sales request for such requirements will be furnished; you could either call up our Head office at Chennai (Tamilnadu, India) or even simpler send us an email

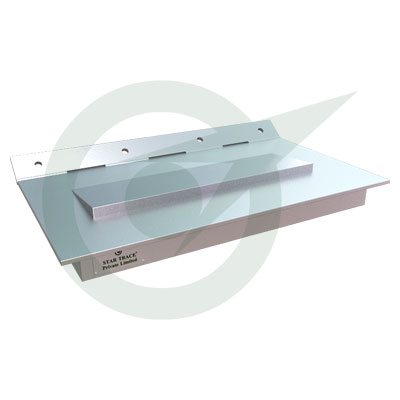

We are well-reputed manufacturer and supplier of brilliant quality stainless steel plate magnets using refined quality raw materials to ensure both quality of plate magnets and customer's satisfaction. Our company offers these permanent plate magnets and many other Magnetic Separators at customers-budget friendly prices. We have highly qualified and experienced professionals who hold specialization in the domain of Magnetic Separator and Plate Magnets manufacturing industry. These plate magnets are designed for easy installation in your granulator's feed tray, and are an economical way to prevent tramp metal from damaging your equipment and contaminating your product.

Star Trace offers a wide spectrum of Industrial Magnetic Separator and Magnetic Plate that are designed to suite varied dimensions and industries. With over quarter of a century experience as manufacturers and suppliers we have been clearly leading in the sale of industrial magnetic plates. The Plate Magnets are a food grade magnet used widely in processing. The industrial magnetic plates come into direct contact with edible items in industrial production line & it's mandatory that standards are adhered. The industrial plate magnets are intended to trap ferrous elements that are contaminants in assembly; so they are stationed either at the bottom of a chute or on top of a conveyor to function effectively.

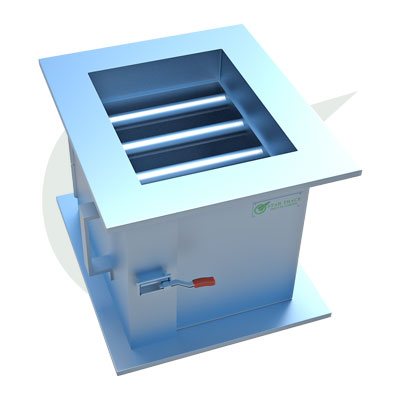

Drawer and Housing magnet is the perfect Magnetic Separator in removing stray tramp metal. The drawer magnet assembly is much suited for free flowing dry materials. The design of Magnetic drawer is so that it traps every ironers material coming into contact with the magnetic grate. As the housing magnet is directly fitted into the process line, body is made completely in SS which matches all food standard norms. The product is available in three different models to suite the extensive use in varied manufacturing areas.

The drawer and housing magnet is referred in many different names like drawer in housing magnet, drawer magnet, magnetic drawer, housing magnet, magnetic grate and grate magnets. Star Trace Solutions Pvt. Ltd. located in Chennai, Tamilnadu, India is a pioneer in manufacturing magnetic grate.

Their rich experience in the field of Magnetic Separator as manufacturers, suppliers and exporters has had hovering sales all through the years. Quality, prompt delivery and custom made solutions are the key features which lead to our success as leading manufacturers, suppliers and exporters. Established in Chennai, Tamilnadu, India all our equipments are MADE IN INDIA.

By constantly updating and revising Magnetic Separator technology, according to market trends we have come out with three uniquely designed for of drawer and Housing magnet. Necessity, kind of separation and budgeting are the few factors that influence the customer in deciding the model for sales.

Installed above the conveyor to remove scrap iron buried in thick material layer. Equipped with a tough,vulcanized rubber belt to remove scrap irons continuously. High-quality Aluminum or Copper wire used. Optional magnetic force at the suspension height rated:500Gs,700Gs,900Gs,1200Gs,1500Gs or above, which will be determined by the requirements of the client. Optional stainless steel clad belt.

Heavy-duty construction.Compact design. Electric motor with chain drive transmission. Departure of the belt can be recrified automatically. Low noise.Low maintenance. Can be suspended either cross belt (perpendicular to the product flow) or inline (parallel above the product flow).

Air- cooled, self cleaning electro magnets are suspended overhead magnets designed for removing ferrous steel and other magnetic materials from your burden during the crushing, screening and sorting processes.

An armour clad conveyor belt travels around the magnet and carries the ferrous material that is drawn upward, away and into collecting hoppers or onto the ground. These units are typically installed either in-line (As in the photo), or cross belt (90 deg. Across the conveyor belt.) They are ideal for removing miscellaneous metallic debris from crushed and recycled material and are designed to provide long-term, trouble free operation. All units are equipped with the required rectifier to power the magnet.

Liquid Line Magnetic Separator- The liquid line magnetic separator is a specially designed compact Inline magnetic separator for removing tramp iron from liquid stream. Very fine particles may be mixed up in the production line which may be due to wear and tare faced by the stainless steel pipeline. It is usual that they collect and even go unnoticed by electronic metal detector. In this dangerous situation liquid line separator plays a very important role.

When inline magnetic separator is fixed in the pipeline of flowing liquid it will trap all the ferrous fragments thus purifying the liquid. The liquids may be anything from water to sauce consistency. Though differences in density have an impact on performance, variations in model and specification takes care of it to serve as effective traps.

Star Trace stationed at Chennai, Tamilnadu, India has been in the business for many years and have developed innumerable products that have undergone continuous up-gradation to match the changing trends in liquid line magnetic separation. Being one among the few top rated manufacturers, suppliers and exporters of Inline magnetic separator we have our technology in place to sustain our leading position in sales.

The Liquid line separator is also referred by the following names Liquid Line separator/ Inline Magnetic separator and liquid line magnetic traps. The construction and working is very simple but efficiency is followed strictly.

STAR TRACE's specialized in manufacturing a wide range of Magnetic Separator for coolant Filtration systems. A team of committed professionals with more than one decade of experience are available, who have designed, developed and supplied Magnetic Separator Filters to various Industries. Star Trace filters are working in different Industries like Engineering, Automobile, Bearings, Spindles, Textile Machinery Rolling Mills, Wire drawing etc.,

The Magnetic Separator filters have been supplied to both Indigenous and Imported Machines and also used as original fitment by many machine tool Builders. The company has wide range of standard Magnetic Separator models to choose from and special / larger system can be designed and supplied as per requirement and application.

Application:

Magnetic Filter are suitable for Cylindrical, Centreless, surface & Internal Grinding Machines, Thread Grinders, Honing Machines, Rolling Mills etc., It is also used as a pre-filter alongwith other types of coolant filters like Paper band or Hydro cyclone filters. The Magnetic Separator unit can be fitted on existing.

Construction & Working Principle:

Magnetic Filter consists of powerful magnetic drum driven by double reduction worm geared motor. The contaminated coolant from the machine is passed is through the gap between the drum and the body. The dust particles are attracted by the drum and a rubber roller squeezes the swarf which is scrapped off by a scrapper plate. The clean coolant is collected is the coolant tank for recirculation to the machine.

We are one of the leading manufacturers and suppliers of the highest quality Magnetic Separator, The Permanent Magnetic Concentrator Separators, which are manufactured using the finest quality raw material to ensure quality of products and customers' satisfaction. These products are machined according to customers' needs and requirements of customers following international quality guidelines for perfection of high capacity Permanent Magnetic Concentrator Separators. Our reliable, durable and the best performing products are available in the market at market leading prices.

Our magnetic sweepers clear important traffic areas of dangerous scrap iron and reduce the possibility of costly flat tires or personal injury. We manufacture and distribute magnetic sweepers for any size job. Push type models clear airless and walkways with 12" - 36" sweeping widths, available with or without easy load release. Hang type sweepers (18" to 96" models) attach to trucks of fork lifts and will lift a 3 ½”.

Long 16 penny nail from 5" off the ground! Our 72" and 96" trailer type sweepers tackle the really big jobs-roads, parking lots, runways and more. All models feature strong, permanent magnetism, quality construction and operate on paved or unpaved surfaces. We're your best source for magnetic sweepers.

Application:

Widely used in workshop, parking lot, lawn, warehouse even air port.

Ideal for ferrous tramp metal separation in gravity systems Star Trace Hump Magnets separators are adaptable to either round pipe or rectangular chute transfer lines.

Employing two heavy duty diverter equipped Spout Magnets positioned so that product flowing through the hump is forced into the magnetic fields. Star Trace humps as Magnetic Separator take advantage of the offset flow of the material and insure maximum tramp metal removal from the product flow.

The hinged magnets are gasketed and clamped tightly to the hump housing for maximum product and dust containment, during processing operation. They swing open for removal of captured tramp metal.

Ruggedly constructed from stainless steel and with welded flange mounting systems to fit chute or pipe applications, Star Trace hump separators are available in different sizes.

Customized Magnetic Separators are available for special application.

Aerodynamically shaped with a solid stainless steel nose cone, the flow through design of the Bullet Magnets allow the Magnetic Separator to be used anywhere in a pneumatic line system. It can be used ahead of processing equipment and bulk load out to assure product purity and protect machinery from tramp metal damage. The nose cone diverter and magnet assembly of the Bullet is designed to maintain a balanced flow through the housing thereby maintaining uniform velocity in line flow. Ideal for dilute phase systems, typical Bullet Magnets applications include: movement of powder and granular flour, chemical, plastic, food stuff, pharmaceutical and mineral materials.

When the two vibrating motor that installed vertically on the sieve relatively rotate, the eccentric block of two vibrating motors produce rated excitation force. The horizontal excitation force cancel each other out, the vertical excitation force is transported to the whole screen surface through the body mass vibration. Materials do the jumping movement on the screen surface to the outlet because of the vertical excitation force. Materials which smaller than the mesh drop into the lower layer and discharge from the outlet after doing the jumping movement. Because of the reasonable screen, after vibrating screen, we can get materials of different concentration particle sizes and done the rating work of materials.

WORKING:

There are guide strips within the bullet magnets, which direct the material onto the bullet face. The Bullet Separator or Magnetic Separator has been specifically designed for very quick and easy cleaning, reducing production downtime to a minimum.

STANDARD FEATURES:

BULLET MAGNETS APPLICATIONS: