The Star Trace Overband Magnetic Separator is capable of handling huge volumes of feeds that need separation of magnetic substances. The built up of the Overband Magnetic Separator is robust and withstands the rough working conditions under which they perform. Overband Magnetic Separator are commonly seen in mining plants where they work continuously without downtime. Not only does the Overband Magnetic Separator find use in mining industries but also in many other applications which need removal of iron from bulk of material.

Processing close to three decenniums of experience in manufacturing magnetic equipment, the Overband Magnetic Separator designed by us has under gone several changes to incorporate latest technology and to perfect its working. Utilizing opportunities we have establishes ourselves as leaders in sales & at the same time earned reputation as trusted manufacturers, suppliers and exporters with clients not only in Chennai (Tamilnadu, India), even globally.

Working of the Overband Magnetic Separator:

Putting the magnetic property into use the Overband Magnetic Separator removes ferrous substances mixed in feeds. With such separation there is recovery of valuable ferrous metal, they also prevent damage to other parts of machines when lead to processing. Positioned between two pulleys is a strong permanent / electro magnet all these are wrapped by a belt which moves once the Overband Magnetic Separator is engaged to work.

The Overband Magnetic Separator is suspended from above over a conveyor belt with close proximity to the feed. Irony objects are attracted by the magnet in the Overband Magnetic Separator and discharged in a separate location.

Salient features of Overband Magnetic Separator:

Applications of Overband Magnetic Separator:

Irrespective of the size of the industry the Overband Magnetic Separators are being used for their effectiveness and trouble free running. Self clean Overband Magnetic Separators are used by manufacturers who handle huge volume of input where as smaller work areas make use of manual cleaning Overband Magnetic Separator. As experienced manufacturers, suppliers and exporters we have a team of knowledgeable engineers who will guide you through in selecting the apt Overband Magnetic Separator. Send us an inquiry and rely on us for all you requirements pertaining to magnetic separation.

We also provide turnkey solutions for a wide range of industries which would be anything from waste recycling to gold processing. To know more about the services rendered by us log on to our website and submit your enquiry to have a detailed discussion with experts.

The only aesthetic equipment to be seen in a manufacturing unit is the Overband magnetic separator. It hangs from above and sarcastically draws all ferrous substances hiding in the conveyor belt running below it. Star Trace as a leading manufacturer designs these separators with robust body to with stand the rough conditions in which it works. The strong permanent magnet is well protected from pollution and working environment changes thus facilitating uninterrupted work flow. Industries which take the help of overband magnetic separator for increasing output and to protect their machinery are:

Features of Overband magnetic separator:

On installing the overband magnetic separator either over a conveyor or in combination with a magnetic pulley the output is sure to increase remarkably.

Its our privilege to share our expertise with you in developing your business. Having set up the overband magnet for hundreds of industries we are well versed in their working. They have also undergone minor changes in the overband magnetic separators for better performance. Constant upgradation is a regular feature at Star Trace.

The overband magnet is kept suspended over a conveyor belt or is used in combination with other magnetic separation devices like magnetic pulley to facilitate in the process of separation. Ferrous particles which are likely to damage the other working components are removed using overband magnet. Some industries use the overband magnetic separators to recover ferrous from waste for recycling. Industries which benefit from overband magnets are:

Variations in size for overband magnet is also provided to suite the existing conveyers. As installation of overband magnet requires no major changes in existing setup they are the most preferred equipment for ferrous recovery.

The Overband Magnetic Separator abbreviated as OBMS is used in effective separation of ferrous substance from a conveyor or from the discharge end of the conveyor. Even small sized ferrous substances tend to cause great damage to machines as well as the final product. To effectively handle this situation OBMS is installed.

Salient features of OBMS / Overband Magnetic separators:

The OBMS designed by Star Trace is put to use by umpteen manufacturers globally to save the other machinery from damage as well as to deliver a superior product devoid of all impurities. Experience our quality standards by purchasing OBMS.

Star Trace reckoned as one of the top players in magnetic separation equipment, serves clients globally with unmatched quality and dedication irrespective of constraints. Permanent overband magnets are quite huge structures but can be introduced into the assembly line without making major changes as they are suspended from above and do not occupy space on the floor. With the help of ropes or fasteners they are hung from above in suitable angle to attract ferrous particles that are conveyed in the belt below. For best results minimum distance between the conveyor and suspended magnet should be maintained for optimal performance. Once the effort of separation is over all the contaminants are removed making it suitable to go to the next stage of production.Furthermore it is important to look into all other aspects to derive a pure substance.

Applications of Overband Magnetic separators:

We are a trusted name in the industry who have been serving clients for the past 25 years. The cross belt magnet which is suspended from above enthusiastically pulls out all ferrous substances from the conveyor above which it is suspended. The strong permanent magnet is capable of retaining its strength at all times without any difference. As the magnet is protected inside a casing there are no chances of it getting damaged. The overband magnetic separators is built to work without downtime. The cross belt magnet is used in combination with other ferrous extraction equipment either to increase output or to get highly refined output. There is no electricity needed for the magnet as it is not an electro magnet.

Industrial uses of Overband Magnetic separators:

The products supplied by Star Trace have stood the test of time and are known for their durability and cost effectiveness.

You can expect a superior product from the market leader StarTrace with unmatched quality and performance. Owing to our experience we are able to manufacture flawless equipment lasting more than its expectancy. The sturdy construction of suspended magnetic separator can be easily introduced into the assembly line for the obvious reason that it only has to be suspended from above and does not occupy moving space like other machinery. This being one of the valid point for taking quick decisions on purchase of suspended magnetic separator. When the overband magnetic separators is at work iron contaminants are quickly pulled up by the magnetic field and discharged into a separate compartment while the rest move with the conveyer without activity.

Attractive features of suspended magnetic separator:

Incorporation of suspended magnets is sure to improve the purity and rate of output.

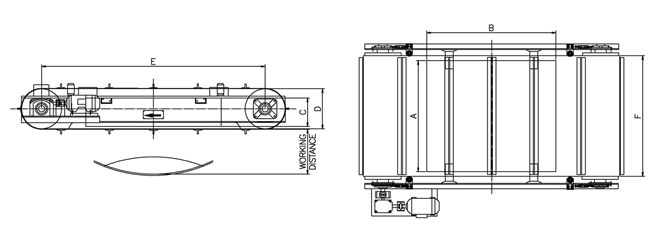

Technical Specification:

| DIMENSIONS AND TECHNICAL DATA | ||||||||

| Type | Belt Width mm | Working distance mm |

Weight kg | Drive KW | Overall dimensions | |||

| Across | Inline | Length | Width | Height | ||||

| OBMS-40/50-15 | 500 | 400 | 120-160 | 440 | 1,5 | 1380 | 1000 | 400 |

| OBMS-40/70-15 | 650 | 400 | 120-160 | 540 | 1,5 | 1580 | 1000 | 400 |

| OBMS-40/90-15 | 800 | 400 | 120-160 | 640 | 1,5 | 1780 | 1000 | 400 |

| OBMS-40/110-15 | 1000 | 400 | 120-160 | 740 | 1,5 | 1980 | 1000 | 400 |

| OBMS-60/50-20 | 500 | 650 | 170-220 | 640 | 1,5 | 1380 | 1200 | 400 |

| OBMS-60/70-20 | 650 | 650 | 170-220 | 780 | 1,5 | 1580 | 1200 | 400 |

| OBMS-60/90-20 | 800 | 650 | 170-220 | 920 | 1,5 | 1780 | 1200 | 400 |

| OBMS-60/110-20 | 1000 | 650 | 170-220 | 1060 | 1,5 | 1980 | 1200 | 400 |

| OBMS-60/130-20 | 1200 | 650 | 170-220 | 1220 | 1,5 | 2180 | 1200 | 400 |

| OBMS-75/70-25 | 650 | 800 | 220-270 | 1200 | 2,2 | 1830 | 1380 | 500 |

| OBMS-75/90-25 | 800 | 800 | 220-270 | 1340 | 2,2 | 2030 | 1380 | 500 |

| OBMS-75/110-25 | 1000 | 800 | 220-270 | 1660 | 2,2 | 2230 | 1380 | 500 |

| OBMS-75/130-25 | 1200 | 800 | 220-270 | 1800 | 2,2 | 2430 | 1380 | 500 |

| OBMS-75/150-25 | 1400 | 800 | 220-270 | 1940 | 2,2 | 2630 | 1380 | 500 |

| OBMS-95/70-30 | 650 | 1000 | 240-320 | 1430 | 2,2 | 1830 | 1580 | 500 |

| OBMS-95/90-30 | 800 | 1000 | 240-320 | 1650 | 2,2 | 2030 | 1580 | 500 |

| OBMS-95/110-30 | 1000 | 1000 | 240-320 | 1870 | 2,2 | 2230 | 1580 | 500 |

| OBMS-95/130-30 | 1200 | 1000 | 240-320 | 2100 | 2,2 | 2430 | 1580 | 500 |

| OBMS-95/150-30 | 1400 | 1000 | 240-320 | 2330 | 2,2 | 2630 | 1580 | 500 |

| OBMS-115/90-35 | 800 | 1200 | 260-350 | 2270 | 3,0 | 2030 | 1780 | 500 |

| OBMS-115/110-35 | 1000 | 1200 | 260-350 | 2250 | 3,0 | 2230 | 1780 | 500 |

| OBMS-115/130-35 | 1200 | 1200 | 260-350 | 2570 | 3,0 | 2430 | 1780 | 500 |

| OBMS-115/150-35 | 1400 | 1200 | 260-350 | 2900 | 3,0 | 2630 | 1780 | 500 |

| OBMS-130/110-35 | 1000 | 1400 | 280-370 | 2580 | 3,0 | 2230 | 1980 | 500 |

| OBMS-130/130-35 | 1200 | 1400 | 280-370 | 2950 | 3,0 | 2430 | 1980 | 500 |

| OBMS-130/150-35 | 1400 | 1400 | 280-370 | 3340 | 3,0 | 2630 | 1980 | 500 |

| OBMS-130/170-35 | 1600 | 1400 | 280-370 | 3750 | 3,0 | 2830 | 1980 | 500 |

| OBMS-150/130-40 | 1200 | 1600 | 300-390 | 3400 | 3,0 | 2430 | 2180 | 500 |

| OBMS-150/150-40 | 1400 | 1600 | 300-390 | 3840 | 3,0 | 2630 | 2180 | 500 |

| OBMS-150-170/40 | 1600 | 1600 | 300-390 | 4310 | 3,0 | 2830 | 2180 | 500 |

| OBMS-150-190/40 | 1800 | 1600 | 300-390 | 4810 | 3,0 | 3030 | 2180 | 500 |

| MAGNET DIMENSIONS | |||||

| a | b | c | d | e | f |

| 420 | 500 | 200 | 220 | 1110 | 470 |

| 420 | 700 | 200 | 220 | 1310 | 470 |

| 420 | 900 | 200 | 220 | 1510 | 470 |

| 420 | 1100 | 200 | 220 | 1710 | 470 |

| 620 | 500 | 200 | 220 | 1110 | 670 |

| 620 | 700 | 200 | 220 | 1310 | 670 |

| 620 | 900 | 200 | 220 | 1510 | 670 |

| 620 | 1100 | 200 | 220 | 1710 | 670 |

| 620 | 1300 | 200 | 220 | 1910 | 670 |

| 770 | 700 | 250 | 320 | 1450 | 830 |

| 770 | 900 | 250 | 320 | 1650 | 830 |

| 770 | 1100 | 250 | 320 | 1850 | 830 |

| 770 | 1300 | 250 | 320 | 2050 | 830 |

| 770 | 1500 | 250 | 320 | 2250 | 830 |

| 970 | 700 | 250 | 320 | 1450 | 1030 |

| 970 | 900 | 250 | 320 | 1650 | 1030 |

| 970 | 1100 | 250 | 320 | 1850 | 1030 |

| 970 | 1300 | 250 | 320 | 2050 | 1030 |

| 970 | 1500 | 250 | 320 | 2250 | 1030 |

| 1170 | 900 | 250 | 320 | 1650 | 1230 |

| 1170 | 1100 | 250 | 320 | 1850 | 1230 |

| 1170 | 1300 | 250 | 320 | 2050 | 1230 |

| 1170 | 1500 | 250 | 320 | 2250 | 1230 |

| 1370 | 1100 | 250 | 320 | 1850 | 1380 |

| 1370 | 1300 | 250 | 320 | 2050 | 1380 |

| 1370 | 1500 | 250 | 320 | 2250 | 1380 |

| 1370 | 1700 | 250 | 320 | 2450 | 1380 |

| 1520 | 1100 | 250 | 320 | 2050 | 1580 |

| 1520 | 1300 | 250 | 320 | 2250 | 1580 |

| 1520 | 1500 | 250 | 320 | 2450 | 1580 |

| 1520 | 1700 | 250 | 320 | 2650 | 1580 |

overband magnetic separators overband magnetic separators manufacturers overband magnetic separators suppliers how does a overband magnetic separators work overband magnetic separators sale overband magnetic separators china overband magnetic separators manufacturers india overband magnetic separators capacity overband magnetic separators design overband magnetic separators wiki overband magnetic separators globally