The Gyratory Screen Separator is one of the most widely used industrial equipment for separation and grading. Occupying a limited floor space the Gyratory Screen Separator works efficiently with very less down time. The number of screens in the Gyratory Screen Separator decides the range of grading, separation of solids from liquids is also workable.

Star Trace is an illustrious manufacture, supplier and exporter of Gyratory Screen Separator with over twenty five years of experience. Head quartered in Chennai (Tamilnadu, India), international standards and quality are maintained in the manufacturing of all the equipment. The Gyratory Screen Separator can also be customized to client requirements so as to bring out desired results.

The Gyratory Screen Separator intends to separate feeds according to size so as to prepare for the final stage of packing or it could be the initial stage where processing is to follow. Removal of impurities is also achieved using the Gyratory Screen Separator, e.g. fiber strands which contaminate starch can be removed by using a single screen Gyratory Screen Separator. Multiple screens can also be used to suite the purpose accordingly.

Functioning of the Gyratory Screen Separator:

The Gyratory Screen Separator or vibro sifter is fitted with a vibratory motor and vibrations are sent across the entire screen area. The circular rotatory motion initiated by the vibratory motor spreads the feed on the screen to facilitate faster separation. The bigger the screen area the larger is the feed handling capacity of the Gyratory Screen Separator. When sieves of different gauss sizes are used the substances that are over sized in each level are let out through tangential opening.

When multiple screens are used, substances of smallest particle size are received at the bottom of the Gyratory Screen Separator opening while the larger ones are collected in the top most outlets. The stacked up screens with different gauss sizes of the Gyratory Screen Separator are readily available with us. Other than for the sale of standard sized Gyratory Screen Separator customized sizes are also delivered on sales request.

Use of Gyratory Screen Separator in food industry:

The food industry is one of the largest users of Gyratory Screen Separator as they refine anything from milk powder to pulses. Several manufacturers, suppliers and exporters pose stiff competition in the sales of Gyratory Screen Separator and we have emerged as the leaders in sales which exhibits our quality. Our equipment has been sold not only in Chennai, Tamilnadu, India but globally.

Pharmaceutical Industry:

The Gyratory Screen Separator is used by the pharmacy companies for refining of powdery substance, shaking away the excess material (that would have gathered during production) from capsules to obtain a neat appearance before packing. Gyratory Screen Separator is also used for removal of foreign substances or contaminants.

Use of Gyratory Screen Separator in paper industry:

It’s surprising that the Gyratory Screen Separator is being used by paper manufacturers. At many stages they play a crucial role for separation. By employing the Gyratory Screen Separator production is not hindered and product quality is enhanced. Sieves of different gauss sizes are put to effective use.

Use of Gyratory Screen Separator in Paint and Ink industry:

Gyratory Screen Separator can effectively separate impurities from inputs which are dry as well as wet. The gauss size of screens varies depending on the requirement of refining and is available with us on sales request.

Chemical Industry using the Gyratory Screen Separator:

The Gyratory Screen Separator plays a crucial role in chemical industry where manual handling is impossible. The Gyratory Screen Separator is used at every stage to rule out contaminants, lumps, mixing and segregation. Special screens with gauss matching particle sizes are delivered by us in short duration. Customized vibro separators have been delivered to a number of customers globally.

Other areas of application:

Dry Separation by Gyratory Screen Separator:

| Commodity | Descriptions |

| Chemicals | Alum, melanin, cellulose acetate, Polyvinyl chloride, phenolics, polystyrene, , caustic soda flake, detergents etc., |

| Wood Products & Pulp | Wood Flour. Wood chips and particle Board |

| Feeds of Animal | Removal of foreign material, bone chips etc., |

| Grains | Cleaning, Grading of Agricultural seeds and grains like rice, wheat, jowar etc., |

| Cosmetic | Removal of foreign substances from cosmetic powders. |

| Food items | Removing hull from rice, coffee beans from chaff, and tea from bags. |

Dry Feeds handled by Gyratory Screen Separator:

Explicit separation of dry materials in different sizes.

| Dry feeds | Descriptions |

| Petrochemicals | Grading and retrieving catalyst pellets etc., |

| Food | Coffee powder, ground coffee, dried milk, sugar, salts, spices, cashew nuts, flour, Maida, dehydrated onion powder. Ground coffee,sugar,spices,flour,dehydrated powders like onion powder, milk powder, salt, spices etc. |

| Pharmaceutical powders | Epsom salts, Boric acid, Aspirin, granulations, sodium bicarbonate, tablet deducting, etc., |

| Fertilizer | Potash, Granulated mixes, urea ammonium, catalyst, nitrate, sulphates and single super phosphates etc., |

| Tea | Grading of tea (CTC and Orthodox) up to 8 grades. |

| Abrasives & Ceramics | Cardorundrum, blasting silica and alumina oxide |

Separation of solids and liquids by Gyratory Screen Separator:

Removing water or dewatering of solid substances from liquid medium.

| Product Handled | Description |

| Disposal of waste | Clarification of water in pulp mills, cannery wastes paunch manure from meat packing, distillery slop etc., |

| Minerals | Separating impurities from kaolin slurry before centrifuging, classification of silica to remove iron impurities etc., |

| Paints and Pigments | Removal of foreign particles from liquid medium. |

| Pulp & Paper | Starch solutions, Screening of adhesives, Paper coatings and Black Liquor. Removal of Pulp and other contaminants from clean & back water. Sizing, scalping of wood chips without any clogging problem. |

| Food | Separation of biogases from sugar melt, slurry cum fiber from starch slurry, clarifying of chocolates liquor, removal of pulp from juice etc., |

| Ceramics | Clarifies and glaze slips for witeware etc |

| Chemicals | Separation of salt from glycerin, clarification of Polyvinyl acetate emulsions, paints & enamels etc., |

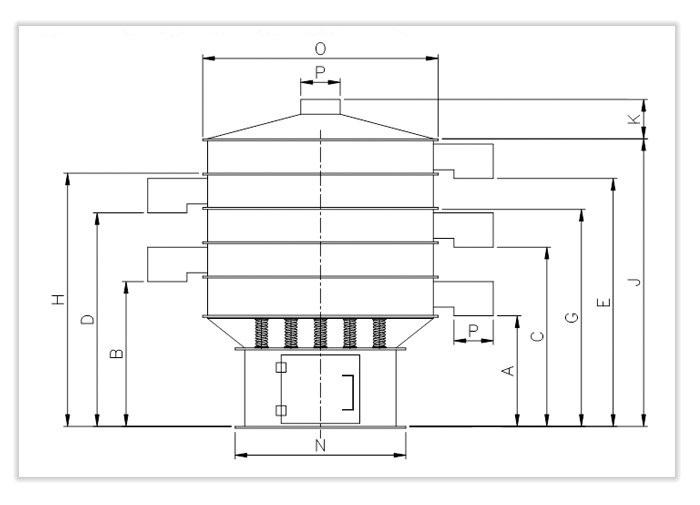

| MODELS AND SPECIFICATION | |||||||||||||

| Model | OD mm |

Motor HP |

A mm |

B mm |

C mm |

D mm |

E mm |

J mm |

K mm |

P mm |

N mm |

G mm |

H mm |

| Mg20 | 455 | 0.25 | 375 | 458 | 541 | 624 | 707 | 797 | 140 | 100 | 435 | 630 | 714 |

| Mg26 | 610 | 0.50 | 400 | 511 | 622 | 733 | 844 | 965 | 110 | 152 | 508 | 743 | 854 |

| Mg34 | 820 | 1.0 | 420 | 580 | 740 | 900 | 1060 | 1240 | 138 | 152 | 600 | 920 | 1080 |

| Mg50 | 1220 | 2.0 | 640 | 805 | 970 | 1135 | 1300 | 1505 | 210 | 203 | 920 | 1175 | 1340 |

| Mg62 | 1525 | 2.0/2.5 | 660 | 872 | 1084 | 1296 | 1508 | 1746 | 250 | 203 | 1085 | 1322 | 1534 |

| Mg74 | 1830 | 2/5.0 | 690 | 925 | 1160 | 1395 | 1630 | 1885 | 254 | 254 | 1265 | 1415 | 1650 |

| Adjustment of Top & Bottom weights in accordance with the diagrams | |

|

0o Lead - Average material will be thrown straight material travel radially. |

|

15o Lead Average materials will begin to spiral material Travel Takes |

|

35o Lead Average materials will give maximum screening pattern material |

|

90o Lead Over size materials does not discharge material tends to |

Separation to precise sizes are possible with the perfectly designed Star Trace Gyratory Screen Separator incorporating the latest in technology and standards. This self-contained equipment is widely used in grading. The mixture to be graded is fed into the gyratory screen separator from the top, at the lower extreme of the equipment is the vibratory motor with eccentric weights.Vibration is created in different directions on the screen and according to their size they pass through the screen and get discharged through the outlet provided at each level. Our gyratory screen separator is designed in such a way that vibration reaches every corner of the screen for perfect output.

Applications of Gyratory screen separatorThe accurate separation, ease of use, easy maintenance, less noisy and durability are distinct qualities that surpass the other competitors and give us a lead.

With over two and a half decades of experience in the field of manufacturing we are delighted to introduce ourselves as leading gyro screen manufacturers.Gyro screens come in different diameters and mesh sizes to grade in accordance to the output required. As an equipment they come with two to three gyro screen which again ca be custom made. Almost all products used in our day to day life would have passed through the gyro screen separator, so extensive is its use. A simple example to which you can easily relate is, nuts like almond, & cashew are of uniform size when sold in shops and price varies with size. This is possible only on segregating through the gyro screen. The result of sorting results in

One of the most cost efficient sifters designed by Star Trace is the vibro sifter. Much to the envy of many, our sifters have over taken competitors in sale. Sifters grade products according to size and also shake off excess powder or particles stuck to the finished product. The vibratory motion of the vibro sifter is brought about by vibrating motors fixed at the lower end. Feeding the sifter is from the top and they pass through each screen depending on their permeability. Once they pass through and stagnate on a screen they are discharged via the outlet and collected in bins or collection tanks. Liquids are also refined by using the vibro sifter. Oils like sesame, ground nut etc. tend to carry with them foreign particles, skin of seeds or impurities like fiber. These can be quickly removed by passing them through vibro screen, thus last stage purification is completed and are ready for packing.

Are you looking for Vibro Screen Separators which adhere to quality norms and standards? You have landed in the right page. We are Star Trace Solutions Pvt. Ltd., who have been in the manufacturing segment for over 25 yrs and have clients across the globe. With time gained experience every part of the separator is perfected to give lifelong uninterrupted service.

Salient features of the Vibro screen separator are:Almost all food and food product handling industries have vibro screen separator for segregation into different of grades. Sugar, coffee powder, milk powder, flour, chemicals, edible oils, seeds for agriculture, spices etc. are few of the many industries using vibro screen separators.

As an established market leader we manufacture an array of vibrating, magnetic, lifting, iron ore beneficiation and turn key solutions. The vibratory screen separator is one of our perfected equipment to handle grading. Solids, liquids and powdery substances can be refined without much effort. The vibratory screen separator designed by Star Trace is easy to assemble and dismantle, so changing of screens is a simple process and can be completed within minutes.

Sorting of coffee beans, nuts, grains, spices, cereal, tea, pulp, paper, pharmaceutical, pests, soaps, detergents, pesticides, ceramics etc can be refined by the screen separator. When the vibratory screen separator is fed with ground nut the the sizes that are permissible by the mesh are passed where as the remaining are taken to the next screen thus separation happens. This procedure is geared up by the vibrating motion induced by the vibratory motor. In liquids contamination like fiber, lumps, small stones etc are removed.

The vibrating screen separator delivered by us are designed using quality raw materials and adhering to standard norms. The construction of the vibrating Screen separator is very compact with a vibrating motor at the bottom and screens stacked one above the other. The vibrating motor creates vibration along three planes which covers the whole area of the screen. Outlets are provided at each level of screen for collection into bags or bins.

Refractory and Abrasives materials also use the vibrating screen separator for refining their product of contaminants. The susceptibility to wear and tear is more and screens are made with support mesh to provide strength. Trouble free working is assured to meet with the expected output. Further the vibrating screen separator does not need much down time and the time taken to clean the screens is sufficient. As the installation is very easy operators can clean and set back the screen separator for functioning.

Star Trace Vibro Screen are best in quality as the raw materials that go into the making of it is of premium standers. A neat finish is designed for the exterior and is self contained. The vibratory motor concealed below the equipment produces vibration in different planes to reach the nook and corner of the screen. Further the maintenance of the equipment is convenient and can be handled single handed.

Dairy manufacturers use the vibro screen to refine milk powder of lumps and contaminants like fiber or anything other than powder. Dry fruits, caramel, coco etc are also sent through the screen to remove impurities and lumps facilitating a uniform powdery output.

Starch is used as raw material by many manufacturers. Supplying them in best of standards is mandatory. To attain this the last step is to pass them through vibro screens which removes lumps , fabric strands or plant fiber if present.

Built with trust and experience Star Trace has been the fore runner for many equipment. The vibro separator is one among them and has been used in innumerable industries to grade, refine and segregate products. Quality is achieved in all substances ranging from big to powder. The mesh size is to be designed according to the product handled. Usually the vibro separator screen is seen in twos or threes for step by step gradation.

Industries which make use of vibro separators are:In the soap and detergent manufacturing units several vibro separators are engaged depending on the manufacturing capacity of the unit. The vibro screens filter lumps, damp unmixed material and over sized particles in the product stream which tend to play havoc on the appearance and quality of the product.

Star Trace Sieving Machines have been designed absorbing technology and efficiency at our high end technology center. Sieving Machines benefit those resorting to activities like blending, grading, sieving etc. The equipment as such has one or more screens stacked one above the other in compartments. Feeding the substance to be sieved is from the top. Vibrations are imparted to the sieve with the help of vibratory motors which facilitate the process of separation.

Notable features of Sieving Machine are:Consumables like cereals, pulses, grams, flour, sugar, milk powder and many more pass through the sieve to reach us as quality products. Other than these the oil,chemical, mineral, paint and pigment industries extensively make use of the Sieving Machine.

Star Trace is one of the prominent names in the manufacturing segment; who have a long list of clients in India and internationally. Having served clients for the past 25 yrs; we are well aware of the nuances in each equipment as well as in every industry. This gives us the advantage of knowledge which is the key to our success. The rotatory screen separator is a self contained equipment for separation, fitted with vibrating motor at the bottom there are two to three decks arranged one on top of the other with screen of varying mesh sizes. The product to be separated is fed from the top; vibrations created facilitate separation and the rotatory motion moves the material in each screen towards the outlet.

Applications:Take advantage of Star Trace’s expertise and work out solutions that are sure to improve quality and in turn increase brand value. The circular screen separator is one such equipment which is used to grade according to size,remove impurities in liquid stream and to shake off excess particles or crumbs before packing.

Powdered products need to have free flow of the material only then the basic property of fineness will be relieved. Lumps which tend to form during production have to be removed else further lumping will happen and will loose its free flowing nature. The circular screen separators come into play and remove lumps as well as impurities like strands of fiber, pins, paper etc. Industries manufacturing toner powder, graphite, Sodium-bi-carbonate, Stearic acid etc use the Circular screen separator.

Manufacturers of dyes and pigments need to obtain uniformly mixed products devoid of lumps and impurities; only them the pigments and dyes will produce the desired result.Circular screen separator serve as facilitators for the required action.