The Suspension Permanent Magnet from Star Trace is one of the best separation equipment for conveyor belt applications. Placed in a welded framework, the suspension magnet harbors a powerful permanent magnet capable of removing tramp iron from huge volumes.

The suspension permanent magnet is capable of retaining magnetic property even at high temperature and functions with full potential. Its capability of high remanence and coercivity prove them to be good sources of magnetism. The rare earth permanent magnet works without break in full potential.

The magnetic steel of the Suspension Permanent Magnet is chosen from the national famous magnetic material enterprise (national inspection-exempted product) with high purity material and advanced manufacturing process to ensure the magnetic property will not be affected by ambient temperature and mechanical vibration.

The magnetic material in Suspension Permanent Magnet is electroplated on the surface, and assembled with particular clamp by special men, to minimize the difference and make strict anti-corrosion treatment. This Suspension Permanent Magnet series links up with transportation equipments such as all types of belt conveyers, vibration conveyers and charging pipelines to form a complete set to remove the iron magnetic materials under weight of 0.1~0.5kg mixed among the non-magnetic materials to ensure normal & safe operation of the next-step equipment (such as muller, crusher, etc.).

Prominent features of Suspension Permanent Magnet:

Options provided on request

Criteria for selecting suspension permanent magnet

Check the kind of feed material to be subjected for separation

Typical Applications of Suspension Permanent Magnet are:

Suspension Permanent Magnet is used in wide applications like

We Star Trace Solutions Pvt. Ltd. are eminent manufacturers, suppliers and exporters of suspension magnets with more than two decades of experience. The suspension magnets are designed to trap ferrous contaminants of different sizes. By removing the irony substances the raw materials are freed from contamination and at the same time parts of other machinery are protected from damage.

The great advantage of the suspended or suspension permanent magnet is that it can be installed into the process line without making any changes in the prevailing set up. A simple procedure of suspending it up over the conveyor belt with the help of fastening chains so as to create maximum proximity is sufficient for efficient working.

Salient features of suspension permanent magnet

Food, chemical, fertilizer, mining, gypsum and many more industries make use of the suspended magnet.

As a leader in the field of magnetic equipment manufacturing Star Trace offers a wide range of suspended magnets in standard sizes and dimensions. They are equipped to remove tramp iron from the feeds so as to protect the other parts from damage as well as to improve the quality of the product. The suspended magnets are highly durable permanent magnets and do not need electricity for their operation. The Suspension Permanent Magnet attracts ferrous particles that are carried by the conveyor belt. When sufficient amount of tramp is collected it is removed.

Areas of usage:

The permanent suspended magnets are available in standard sizes as well as in customize dimensions to meet the requirement of different clients. Maintaining an optimal distance from the conveyor will fetch best results in retrieval of iron contaminants.

As manufacturers, suppliers and exporters we monitor sales, right from taking up the order to delivery. Quality and specifications are met to global standards as we have clients not only in Chennai,Tamilnadu,India but also globally.

Upon using the Suspension Permanent Magnet there is effective removal of tramp iron from materials that are to undergo successive processing to reach the finished product stage. The setting up of the Suspension Permanent Magnet is simple and easy. The prominent features that contribute to easy installation are

Factors that contribute to effectiveness

The Suspension Permanent Magnets sales by Star Trace have been done across many industries nationally and globally. Quality and cost effectiveness as a rare combination can be seen in all our equipment, which we owe to our efficient engineers and the experience we gained over the past 25 years. Associate with us to experience the truth behind Suspension Permanent Magnet like many of our valued clients.

An effective method to bring about a quality product for sale is to follow strict quality checkers and rule out existence of contaminants. Following processing techniques without removal of impurities would make no improvement in the end product. One of the common methods to remove tramp iron particles from a product stream is to employ a suspension trap magnet or suspension permanent magnet.

The positioning of the suspended tramp magnet is over a conveyor belt from which iron impurities are removed. Placing the suspension magnet at minimal possible distance paves the way for maximum harnessing of impurities.

Note worthy features of suspension trap magnet.

Food, chemical, quarries, cement, garbage etc. are few of the industries that make use of suspension trap magnet. Serving clients globally needs adherence to global standards which is strictly followed by us.

Nurtured by scientific approach and technology, Star Trace is a leading manufacturer of suspension magnet and a plethora of magnetic equipment which are widely used by client across the globe. Our streamlined and systematic approach in manufacturing, combined with stringent quality checks has helped us in bring out quality products.

The suspension magnet is suspended from above over a conveyor belt that carries raw material which needs to be purified of iron contaminants. No rearrangement of factory set us is needed as they are to be set up over a conveyor belt. Permanent magnets with high intensity are used to bring about effective separation. The distance between the conveyor and suspension magnet has to be kept to a minimum for effective ferrous removal. Automatic and self cleaning models are available in different dimensional specifications.

Applications:

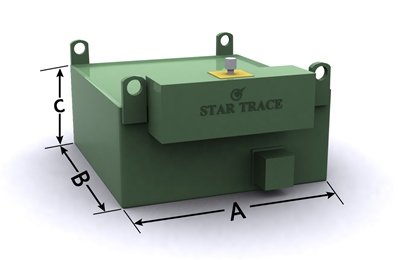

| Model No | Belt width(mm) | Suspension height(≤mm) | Materials Thickness(≤mm) | Weight(kg) | Belt speed(≤m/s) | Overall dimension(mm) | ||

| A | B | C | ||||||

| STPS-115 | 400 | 125 | 60 | 115 | 4.5 | 400 | 300 | 230 |

| STPS-65 | 400 | 75 | 30 | 65 | 4.5 | 400 | 250 | 140 |

| STPS-206 | 500 | 150 | 90 | 206 | 4.5 | 500 | 350 | 260 |

| STPS-96 | 500 | 100 | 50 | 96 | 4.5 | 500 | 260 | 160 |

| STPS-295 | 600 | 175 | 120 | 295 | 4.5 | 600 | 450 | 280 |

| STPS-158 | 600 | 130 | 60 | 158 | 4.5 | 600 | 350 | 180 |

| STPS-450 | 650 | 200 | 150 | 450 | 4.5 | 650 | 600 | 300 |

| STPS-450 | 650 | 200 | 150 | 450 | 4.5 | 650 | 400 | 300 |

| STPS-680 | 800 | 250 | 200 | 680 | 4.5 | 950 | 950 | 380 |

| STPS-550 | 800 | 200 | 150 | 550 | 4.5 | 800 | 600 | 300 |

| STPS-1180 | 1000 | 300 | 250 | 1180 | 4.5 | 1100 | 1000 | 380 |

| STPS-1670 | 1200 | 350 | 300 | 1670 | 4.5 | 1300 | 1340 | 420 |

| STPS-2350 | 1400 | 400 | 350 | 2350 | 4.5 | 1500 | 1500 | 420 |

| STPS-2850 | 1600 | 450 | 400 | 2850 | 4.5 | 1750 | 1750 | 460 |