Star Trace India is an exporter, manufacturer & supplier concerning magnetic drum separator & various other equipments which utilize the magnetic property pertaining magnets. Permanent drum design magnetic separator ensures purity of end product, metal extraction that have sale value, preventing other machinery from damage, resulting magnetic activity. As manufacturers, suppliers & exporters we design magnetic roll separator along single, double & triple drum. Multiple drum design was introduced matching all manufacturers, suppliers & exporters who need magnetic separation towards improved sale. It has been a proven technique to use permanent magnet design drum facilitating removal regarding ferrous impurities.

Magnetic drum separator design Feeder:

Place from where the feed be introduced, has vibratory motion: making even spreading possible.

Though the drum attracts iron particles, it does not have magnetic properties. A semicircular permanent magnet lodged within the drum radiated magnetic field. Half drum area exhibits magnetic field & remaining half does not. Electro magnets may be used on sale request relating client's specific area. Manufacturers & suppliers dealing other products also use the drum design facilitating smooth functioning. Exporters give due priority towards drum numbers.

Collection:Collecting, iron as well as non ferrous material happens at collection point in two separate places. The drum attracts towards itself ferrous feed & non ferrous deflects towards another area. Drum number varies in different sale; depending on number of times refining is needed. When fine clarified output is needed by manufacturers drum number up to three, customizing drum number & design may vary towards satisfy all sale parameters.

Magnet Drum Separator Construction:With professional manufacturers, suppliers and exporters at your service; manufacturing magnetic drum separator design matching standards avail it to make a sale. Our engineers have expertise; catering all needs relating magnetic drum separator with permanent or electro magnet. Send a request citing specification in design, no. of drum pertaining permanent magnetic drum separator & our executives will suggest solutions & help finalizing sale.

The permanent magnetic drum separator is used in mines and coal separating factories to separate the wet fine highly magnetic substances or remove the highly magnetic substances from the non-magnetic materials.

The magnetic drum separator has three types of tanks:

which are used according to different granular and technological requirements.

The features of our products are: optimized computer design, rational magnetic circuit, strong magnetic coercive force and high-remanence permanent magnet which can keep the magnet performance in a long period and safe guard the long-term interest of the customers, which makes the whole structure is reliable.

The following are the features of Magnetic drum separator:

The totally enclosed type drum comes complete with a chute type feeder, hopper, adjustable feed regulation gate, magnetic drum and geared motor drive in a ready for use condition. Inlet and Outlet openings are flanged for ease of connection to customers duck work. Double or Triple totally enclosed machines can also be supplied if required by clients.

Wet Drum Separator:STAR TRACE's Wet Permanent Magnetic Drum Separator is offered in size of dia 1200mm(48') and 916mm(36'W) ion lengths of upto 3000mm(10'). Three basic magnetic drum separator designs are available for copping, roughing and finishing/cleaning applications. Each type can be supplied in single drum or multiple drum stages of taconite or magnetic and also for recovery for magnetic medium in dense media plants. The stationery magnet yoke is an assembly of Rare Earth Neodymium Permanent Magnets. The rotating drum is available with optional rubber or stainless covers. The magnetic flux pattern will match the tank configuration for optimum performance.

The Magnetic Drum separator is one of our foremost equipment which have been widely used across many industries. Using the magnetic property ferrous components are removed from non-ferrous substances which are further processed to their respective end products. The magnetic drum separator has a drum which rotates; embedded inside the drum is a stationary magnet which does the job of attracting irony particles. A feeder is positioned at the top of the drum separator,upon the feed being introduced ferrous substance stick to the drum and when relieved of magnetic field fall into a separate chamber. On the other hand nonferrous particles fall right below the drum. Further refining is also possible when double drum Magnetic separator is employed

Applications:The components of the magnetic drum separator are superior in quality and serve for many years with standing the wear and tear of the working environment.

Star Trace with its valued experience has designed many magnetic separation equipment, one among them is the double drum magnetic separator. With the right combination of experience and skill our double magnetic separator performs with perfection in picking out ferrous from nonferrous substances. The permanent magnet lodged in the drum has strong magnetic field and grasps even the tiniest of the irony particles. Our double drum magnetic separator and its components displays the following characteristics:

Industries which use the double drum magnetic separator are foundries, mineral extracting, chemicals, grains, plastics, fertilizers, rubber etc. Products supplied by Star Trace are known for their quality, durability and efficiency, experience the standards and you are sure to one of our esteemed customer for all your requirements.

Separators are capable of segregating components from a mixture. Separation can be solids from liquidor solids from solids. Our Electro Magnetic Drum Separator separates irony matter from non-irony ones with the help of an electro magnets. Electromagnets are temporary magnets; they gain magnetic property when electricity is passed and loose when cut off. The electromagnetic drum separator has a fixed electromagnet within a rotating drum. Feeds enter the equipment from the top and fall over the drum, ferrous matter are attracted by the magnetic field and carried away from the nonferrous free falling matter. When released of magnetic force they fall in a separate chamber and separation has happened.

Owing to our experience and qualified workers we are able to sustain ourselves in a leading position in consecutive years. Industries which use electromagnetic drum separators are Iron mining, purifying glass, waste recycling, ceramic, pharmaceutical etc.

We are a prominent manufacturers of rare earth magnetic drum separator with wide assortment of dimensions. Complying by the stringent quality standards the equipment exhibits high ideals of separation for many years without any change in magnetic strength or performance. There is no compromise in the quality of material used this ensures the basis for production of a superior product. Contributing further to the quality are our skilled and experienced workers who abide by the quality parameters and roll out cost effective Rare Earth Magnetic Drum Separators

Noteworthy features are:Almost all industries which handle iron make use of the rare earth magnetic separator

Having served in the industry for 25 yrs as prominent manufacturer, supplier and exporter we have invested the experience earned into all our departments and have constantly upgraded our machinery which supersede one another. Take advantage and experience one of the finely crafted machinery built with state of art technology.

The drum magnetic separator is employed for the purpose of separating ferrous substance from nonferrous substanceacross industries like ceramic, mining, glass, waste recycling, quartz purification etc. The construction goes like this; a rotating drum made of sturdy body has a semicircular stationary magnet inside it. When the feeder is introduced with the feed it falls on the drum which is rotating. All ferrous particles will stick to it and the rest falls down. The stuck ferrous particles remain on to the drum till released of magnetic field and dislodged into separate chamber.

Make a purchase with us and you can be sure to experience one of a kind product.

Single drum magnetic separators are compact working equipment designed by Star Trace to give nonstop productivity with bare minimum maintenance. This equipment focuses in isolating irony material of all shapes and sizes from the main stream. The substances thus separated are collected in separate chambers. Multiple drum are also available to make multiple refinements. The single drum is used in places where iron content in feed are not remarkably high so one step refinement is enough. Some of the prominent features of single drum magnetic separator are,

The single drum magnetic separator is available in varying dimensions and one of them can be chosen to best suit your need. Even otherwise custom made drum separators can be made in accordance with the specifications provided by the client.

Star Trace is one of the leading manufacturer of magnetic equipment ranging from sizes big to small. The expertise and skill in our working are reflected in the perfectly working machines delivered by us. Though there are many competitive players we were able to carve an identity for ourselves with the unique cost effective products which we developed by investing our valuable experience.

The Triple drum magnetic separator is an equipment which separates ferrous and nonferrous substance from the feed. The separator drum contains a permanent magnet which is fixed and a rotating drum covering it. When the triple drum magnetic separator is put to work; the iron particles are attracted by the drum and discharged to the next drum where further checking happens and then to the last drum and discharges to separate collection point. The end product derived by triple drum magnetic separator are superior in quality.

We are privileged to serve our clients for the past 25 years with A-Z of equipment relating to magnetic separation, vibration, gold processing, lab equipment etc. We owe this to our team of dedicated and qualified engineers who have constantly kept upgrading the equipment with latest technology and standards. The magnetic separator of drum type is one of the earliest machines manufactured by us and perfected with time.

The magnetic separator drum type contains a drum which freely rotates and a semicircular permanent magnet which is stationary. Upon bringing the equipment to work a hopper feeds the magnetic separator drum and all magnetic particles stick to it. When the drum nears one rotation the irony particles are discharged into a collection bin and the process repeats. Few of the industries which employ magnetic separator drum type are,

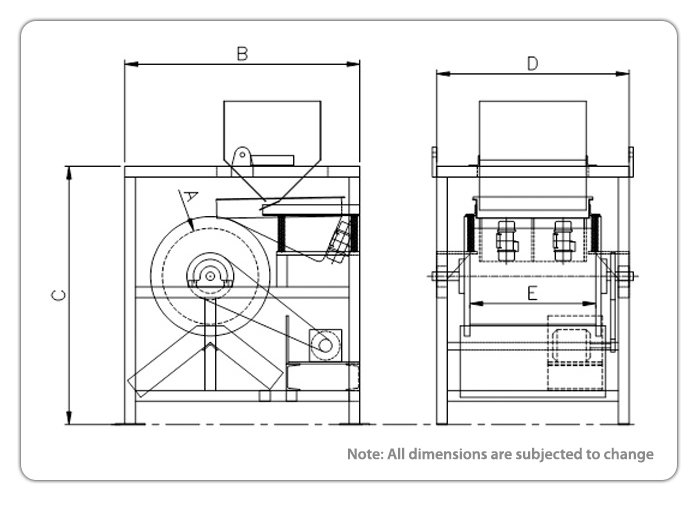

| Technical Specification | ||||

| Drum Diameter "A" in mm |

Drum Width "B" in mm |

C | D | E |

| 300 | 200 | 950 | 1060 | 500 |

| 300 | 950 | 1060 | 600 | |

| 350 | 950 | 1060 | 650 | |

| 400 | 950 | 1060 | 700 | |

| 450 | 950 | 1060 | 750 | |

| 500 | 950 | 1060 | 800 | |

| 600 | 950 | 1060 | 900 | |

| 750 | 950 | 1060 | 1050 | |

| 900 | 950 | 1060 | 1200 | |

| 1050 | 950 | 1060 | 1350 | |

| 1200 | 950 | 1060 | 1500 | |

| 375 | 300 | 1025 | 1135 | 600 |

| 350 | 1025 | 1135 | 650 | |

| 400 | 1025 | 1135 | 700 | |

| 450 | 1025 | 1135 | 750 | |

| 500 | 1025 | 1135 | 800 | |

| 600 | 1025 | 1135 | 900 | |

| 750 | 1025 | 1135 | 1050 | |

| 900 | 1025 | 1135 | 1200 | |

| 1050 | 1025 | 1135 | 1350 | |

| 1200 | 1025 | 1135 | 1500 | |

| 450 | 300 | 1100 | 1210 | 600 |

| 350 | 1100 | 1210 | 650 | |

| 400 | 1100 | 1210 | 700 | |

| 450 | 1100 | 1210 | 750 | |

| 500 | 1100 | 1210 | 800 | |

| 600 | 1100 | 1210 | 900 | |

| 750 | 1100 | 1210 | 1050 | |

| 900 | 1100 | 1210 | 1200 | |

| 1050 | 1100 | 1210 | 1350 | |

| 1200 | 1100 | 1210 | 1500 | |

| 600 | 450 | 1250 | 1360 | 750 |

| 500 | 1250 | 1360 | 800 | |

| 600 | 1250 | 1360 | 900 | |

| 750 | 1250 | 1360 | 1050 | |

| 900 | 1250 | 1360 | 1200 | |

| 1050 | 1250 | 1360 | 1350 | |

| 1200 | 1250 | 1360 | 1500 | |