Star Trace Suspended Permanent Magnets are designed for high separation performance in over-the- belt conveyor applications. These heavy duty permanent magnets incorporation all welded construction are particularly effective in removing tramp metal in high volume applications.

Produces strong magnetic field attraction. The separator body adopts rare earth permanent magnetic materials featuring high remanence, high coercivity and high magnetic energy as magnetic source. The magnetic property is persistent with high temperature stability.

The magnetic steel is chosen from the national famous magnetic material enterprise (national inspection-exempted product) with high purity material and advanced manufacturing process to ensure the magnetic property will not affected by ambient temperature and mechanical vibration.

The magnetic material is electroplated on the surface, and assembled with particular clamp by special man, to minimize the difference and make strict anti-corrosion treatment. This series links up with transportation equipments such as all types of belt conveyers, vibration conveyers and charging pipelines to form a complete set to remove the iron magnetic materials under weight of 0.1~0.5kg mixed among the non-magnetic materials to ensure normal & safe operation of the next-step equipment (such as muller, crusher, etc.).

The following are the features of SUSPENDED PERMANENT MAGNET:

Options:

Selection:

Selection this type magnetic separator depends on the

Typical Applications are:

It used in wide applications like

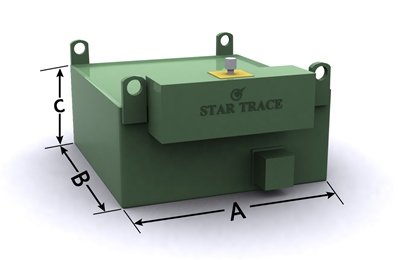

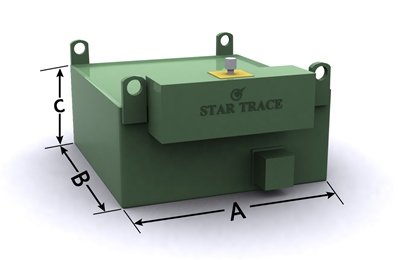

| Model No | Belt width(mm) | Suspension height(≤mm) | Materials Thickness(≤mm) | Weight(kg) | Belt speed(≤m/s) | Overall dimension(mm) | ||

| A | B | C | ||||||

| STPS-115 | 400 | 125 | 60 | 115 | 4.5 | 400 | 300 | 230 |

| STPS-65 | 400 | 75 | 30 | 65 | 4.5 | 400 | 250 | 140 |

| STPS-206 | 500 | 150 | 90 | 206 | 4.5 | 500 | 350 | 260 |

| STPS-96 | 500 | 100 | 50 | 96 | 4.5 | 500 | 260 | 160 |

| STPS-295 | 600 | 175 | 120 | 295 | 4.5 | 600 | 450 | 280 |

| STPS-158 | 600 | 130 | 60 | 158 | 4.5 | 600 | 350 | 180 |

| STPS-450 | 650 | 200 | 150 | 450 | 4.5 | 650 | 600 | 300 |

| STPS-450 | 650 | 200 | 150 | 450 | 4.5 | 650 | 400 | 300 |

| STPS-680 | 800 | 250 | 200 | 680 | 4.5 | 950 | 950 | 380 |

| STPS-550 | 800 | 200 | 150 | 550 | 4.5 | 800 | 600 | 300 |

| STPS-1180 | 1000 | 300 | 250 | 1180 | 4.5 | 1100 | 1000 | 380 |

| STPS-1670 | 1200 | 350 | 300 | 1670 | 4.5 | 1300 | 1340 | 420 |

| STPS-2350 | 1400 | 400 | 350 | 2350 | 4.5 | 1500 | 1500 | 420 |

| STPS-2850 | 1600 | 450 | 400 | 2850 | 4.5 | 1750 | 1750 | 460 |

The Suspension Electro Magnet is one of the preeminent equipment to separate ferrous substances from huge volume of input. They bear the advantage of deep reach and the convenience of turning ON / OFF when required. The Suspension Electro Magnet dangles above a conveyor belt or vibrating bed to pick up irony substances.

Looking into the built up of the Suspension Electro Magnet it has a series of copper or aluminum coils wound around it and immersed in transformer oil to curtail overheating and subsequent shorting. Another option to bring down temperature is to blow air. The operating height of Suspension Electro Magnet is crucial as best results are achieved by maintaining the recommended height, they may vary from 150 mm to 450 mm depending on the model chosen. Suspension Electro Magnet has control panel to handle the operations.

The Suspension Electro Magnet is a dominant electro magnet which is suspended over a conveying system that is part of the production line and carries the feed to the next process. While setting up the Suspension Electro Magnet it should be made sure that the access is convenient so as to carry out maintenance process at regular intervals. It should be doubly ensured that integral parts like pulleys and idler roller are not magnetized by the working of the Suspension Electro Magnet.

The Suspension Electro Magnet comes in two models (i) Manual cleaning (ii) Self-cleaning, lets discuss these models in detail.

(i) Manual cleaning

As the name conveys the manual cleaning method involves labor to remove the collected tramp, practically this model of Suspension Electro Magnet is advisable for installation in process lines where contamination of iron is meager else cleaning would consume a lot of time and delay the production.

(ii) Self-cleaning

These are Suspension Electro Magnet which take to automatic cleaning of tramp iron with a complete set up of working parts to facilitate continuous cleaning. These Self-cleaning models of Suspension Electro Magnet are recommended in applications that involve huge inputs and at the same time the level of ferrous contamination is also high.

Significant features of Suspension Electro Magnet:

Available options:

The following are the features of Electro Suspension Magnet:

Suspension Electro Magnet is a reliable source for recovery of ferrous substance, they are used in several industries.

The Suspension Electro Magnet sale by Star Trace has been remarkable for it meets international standards and has served clients globally from its headquarters in Chennai (Tamilnadu, India). As reputed manufacturer supplier and exporter sales was always done to match the requirements of clients.

| STR Model | Magnet Dimensions mm | Magnet Height mm | Magnet Voltage VDC | Magnet Wattage | Approx Weight Kgs |

| STR 241 | 600 X 600 | 550 | 115 | 1650 | 430 |

| STR 301 | 750 X 750 | 650 | 115 | 2700 | 700 |

| STR 361 | 900 X 900 | 500 | 115 | 3800 | 1050 |

| STR 422 | 1050 X 1050 | 550 | 230 | 5000 | 1600 |

| STR 482 | 1200 X 1200 | 600 | 230 | 6600 | 2250 |

| STR 542 | 1350 X 1350 | 650 | 230 | 8000 | 3150 |

| STR 602 | 1500 X 1500 | 750 | 230 | 10000 | 4000 |

| STR 662 | 1650 X 1650 | 800 | 230 | 12250 | 5200 |

| STR 722 | 1800 X 1800 | 800 | 230 | 14500 | 7250 |

| STR 782 | 2000 X 2000 | 900 | 230 | 17000 | 9100 |

Star Trace’s Electro Suspension Magnets are one of a kind as they are devoid of errors; commonly prevalent among suspension magnets. Ruling out of errors was possible because of the experience gained over the years as well as the approach of bringing out better versions each time which supersedes the previous.

Electro Suspension Magnets are temporary magnets for they gain magnetic property when electricity is passed and get demagnetized when power supply is cut off. Though one may think that using electricity is adding to the operating cost, the advantages are many and production rate will increase. It iswise to use Electro Suspension Magnets in industries where the concentration of ferrous is high; either for extraction or as contaminant. Cleaning the magnet is less cumbersome when compared to permanent magnet; the only thing that has to be done is stop the power supply and all ferrous particles stuck to the face of the Electro Suspension Magnet will fall off and immediately it can be resumed to work by facilitating the power supply. Industries using electro suspension magnets areFoundry, Mining, waste recovery, fertilizer, ceramic etc.

We are one of the distinguished manufacturers, suppliers and exporters of suspension magnets which are widely used over conveyors to trap traces of ferrous particles. Removal of ferrous particles will relieve the process flow of contaminants as well as protect the other parts of the machinery from damage.

The suspended magnet can be installed over any working process line without making changes to the existing set up. All that has to be done is suspend it from above with the help of the suspension chains fastened in it such that maximum proximity is attained. Work begins automatically and effective separation is achieved.

A few of the salient features are,Acknowledging the effectiveness and easy installation of suspended magnets they have been installed in industries like food production, foundry, chemical, fertilizer, gypsum, ores etc.

Star Trace being the unprecedented leader in the field of magnets; offers suspended magnets in different dimensions to commendablyremove tramp iron from process line which tend to damage the machine parts and contribute to contamination. The suspended magnet is a high intensity permanent magnet with durable chains for suspension. Upon the magnet being suspended over the conveyor belt it attracts tramp iron to its face. When sufficient ferrous contaminants have been removed they can be moved off the process line and cleaned. Self-cleaning mechanism suspended magnets are available to fasten the process.

Applications:Permanent suspended magnets are designed in different dimensions to suite the varied needs of clients. For efficient retrieval of tramp iron its best to have suspended magnets that are a little bigger than the conveyor. Minimizing the distance between the conveyor and suspended magnet will also count on the efficient retrieval.

One of the simplest yet effective way of removing tramp iron from a flow of raw material or processedmaterial is by putting the permanent suspension magnet to use. To justify on it being labeled as simplest, here are the points:

The permanent suspension magnets offered by Star Trace have been used across many industries nationally and internationally. Quality and cost effectiveness as a rare combination can be seen in all our equipment, which we owe to our efficient engineers and the experience we gained over the past 25 years. Associate with us to experience the truth behind it like many of our valued clients.

As we all know to bring out a quality product there are many processes that have to be followed. On one hand the necessary processing has to be done and on the other hand removal of impurities should take place to facilitate the processof bringing out a quality product. Suspension Trap Magnet plays its part by removing tramp Iron particles from a product stream.

The suspended Trap Magnet is usually kept suspended over a conveyor from which iron particles have to be removed. The distance between the suspension magnet and the product stream must be kept to a minimum to ensure maximum utilization of suspension trap magnet.

Impressive features of Suspension Trap MagnetIndustries using suspension Trap magnet are cement plants, grains, food products, chemicals, quarries, garbage retrieval etc.

Fostered by twenty five years of valuable experience we stand out from the rest of the competitors in the field. With meticulous and systematic working we have framed rules which ensure quality, durability and dependability. Suspension magnets are usually suspended over a moving conveyor and thus they acquire the name Conveyor Suspension Magnet.

To put the Conveyor Suspension Magnet to use no rearrangement of the factory set up is needed; they can just be suspended over the conveyor without disturbing the working of other machinery. With a rough estimation of how much iron is recovered a permanent or electro magnet can be employed. Distance between the magnet and conveyor should be kept to a reasonable minimum to maximize efficiency. Self-cleaning and automatic models are also available.

Industrial use of Conveyor Suspension Magnets are: