We Star Trace Solutions Pvt. Ltd. are one of the fast growing manufacturers, exporters and suppliers dealing with magnetic head pulley of various specifications. We have grown amid competition from competitors and this we dedicate to the strict quality checker and continuous incorporation of new technology into our manufacturing process. Our magnetic head pulley is sold globally as we meet international standards.

The popularly known magnetic head pulley is used widely in industries for separation of magnetic material from non-magnetic substances. They are used in almost every other industry where this necessity of separation arises. In particular the food industry uses to magnetic head pulley to increase the quality of end product. Raw materials are subjected to the magnetic head pulley which have chances of contamination of ferrous material which would lower the quality as well as damage other parts of the machines it passes through. Introducing a magnetic head pulley into the process stream is sure to have a positive impact on sales.

Construction of magnetic pulley:

The magnetic head pulley has an easy to understand construction and operation. The parts that go into the making of the magnetic head pulley are the magnetic head of the pulley belts to convey, permanent magnet in the pulley and a diverter. The raw materials that is to be cleansed of iron impurities is fed on to the conveyor and when they reach the magnetic head pulley irony particles if any will stick to the conveyor while the others freely fall down. When the conveyor moves further the ferrous particles are relieved of the magnetic field and drop down. To avoid mixing up of separated feeds a diverter is positioned.

The magnetic pulley head has 360 degree magnetic core, shielded by stainless steel covering made with ss304 & an axis for rotation. This is a sturdy structure around permanent magnet which withstands continuous functioning of the Magnetic Pulley.

Trends and requirements for sales are changing not only in Chennai, Tamilnadu and India but also globally. Star Trace; as dominant manufacturers, suppliers and exporters have lived up to the expectation of clients with overwhelming sales one such example is the Magnetic Pulley. Eatables and cooking ingredients need high levels of purification as they go directly for consumption; machines which are highly efficient such as the Magnetic Pulley show high success percentage. Associate with us & benefit from our experience as manufacturers, suppliers & exporters.

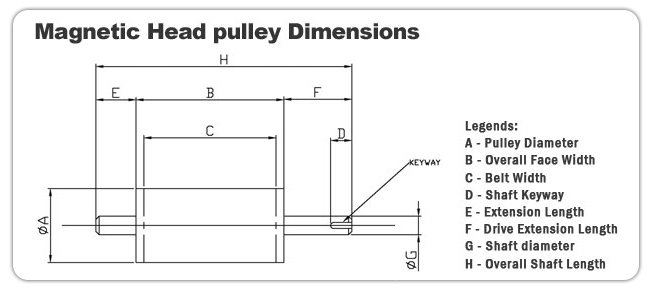

| (A) PULLEY DIAMETER in mm | (B) OVERALL FACE WIDTH in mm | (C) BELT WIDTH in mm | (D) KEYWAY LENGTH in mm | (E) EXTENSION LENGTH in mm | (F) DRIVE EXTENSION LENGTH in mm | (G) SHAFT DIAMETER in mm | KEYWAY SIZE in mm | APPROX WEIGHT in kg |

| 200 | 250 | 200 | 75 | 150 | 230 | 35 | 10 X 5 | 30 |

| 300 | 250 | 75 | 150 | 230 | 35 | 10 X 5 | 34 | |

| 350 | 300 | 75 | 150 | 230 | 35 | 10 X 5 | 45 | |

| 400 | 350 | 75 | 150 | 230 | 35 | 10 X 5 | 50 | |

| 450 | 400 | 75 | 150 | 230 | 35 | 10 X 5 | 56 | |

| 500 | 450 | 75 | 150 | 230 | 35 | 10 X 5 | 59 | |

| 550 | 500 | 75 | 150 | 230 | 35 | 10 X 5 | 63 | |

| 650 | 600 | 75 | 150 | 230 | 35 | 10 X 5 | 70 | |

| 800 | 750 | 75 | 150 | 230 | 35 | 10 X 5 | 92 | |

| 950 | 900 | 75 | 150 | 230 | 35 | 10 X 5 | 104 | |

| 300 | 350 | 300 | 100 | 200 | 300 | 50 | 12.5 X 6.5 | 104 |

| 400 | 350 | 100 | 200 | 300 | 50 | 12.5 X 6.5 | 117 | |

| 450 | 400 | 100 | 200 | 300 | 50 | 12.5 X 6.5 | 126 | |

| 500 | 450 | 100 | 200 | 300 | 50 | 12.5 X 6.5 | 153 | |

| 550 | 500 | 100 | 230 | 330 | 50 | 12.5 X 6.5 | 164 | |

| 650 | 600 | 125 | 230 | 330 | 70 | 16 X 8 | 189 | |

| 800 | 750 | 125 | 230 | 350 | 70 | 16 X 8 | 230 | |

| 950 | 900 | 125 | 230 | 350 | 70 | 16 X 8 | 272 | |

| 1100 | 1050 | 125 | 250 | 380 | 70 | 16 X 8 | 313 | |

| 1250 | 1200 | 125 | 250 | 380 | 70 | 16 X 8 | 358 | |

| 380 | 350 | 300 | 100 | 200 | 300 | 50 | 12.5 X 6.5 | 137 |

| 400 | 350 | 100 | 200 | 300 | 50 | 12.5 X 6.5 | 167 | |

| 450 | 400 | 125 | 230 | 350 | 60 | 16 X 8 | 169 | |

| 500 | 450 | 125 | 230 | 350 | 60 | 16 X 8 | 209 | |

| 550 | 500 | 125 | 250 | 380 | 60 | 16 X 8 | 223 | |

| 650 | 600 | 125 | 280 | 400 | 75 | 19 X 10 | 259 | |

| 800 | 750 | 150 | 280 | 430 | 75 | 19 X 10 | 335 | |

| 950 | 900 | 150 | 280 | 430 | 75 | 19 X 10 | 394 | |

| 1100 | 1050 | 150 | 300 | 450 | 75 | 19 X 10 | 457 | |

| 1250 | 1200 | 150 | 300 | 450 | 75 | 19 X 10 | 518 | |

| 450 | 350 | 300 | 125 | 230 | 350 | 60 | 16 X 8 | 178 |

| 400 | 350 | 125 | 230 | 350 | 60 | 16 X 8 | 203 | |

| 450 | 400 | 125 | 230 | 350 | 60 | 16 X 8 | 234 | |

| 500 | 450 | 125 | 230 | 350 | 60 | 16 X 8 | 297 | |

| 550 | 500 | 125 | 250 | 380 | 75 | 19 X 10 | 306 | |

| 650 | 600 | 125 | 280 | 400 | 75 | 19 X 10 | 367 | |

| 800 | 750 | 150 | 280 | 430 | 75 | 19 X 10 | 468 | |

| 950 | 900 | 150 | 280 | 430 | 75 | 19 X 10 | 574 | |

| 1100 | 1050 | 150 | 300 | 450 | 75 | 19 X 10 | 673 | |

| 1250 | 1200 | 150 | 300 | 450 | 75 | 19 X 10 | 772 | |

| 500 | 400 | 350 | 125 | 230 | 350 | 60 | 16 X 8 | 248 |

| 450 | 400 | 125 | 230 | 350 | 60 | 16 X 8 | 275 | |

| 500 | 450 | 125 | 250 | 380 | 60 | 16 X 8 | 311 | |

| 550 | 500 | 125 | 250 | 380 | 60 | 16 X 8 | 349 | |

| 660 | 600 | 125 | 280 | 400 | 75 | 19 X 10 | 414 | |

| 810 | 750 | 150 | 280 | 430 | 75 | 19 X 10 | 554 | |

| 960 | 900 | 150 | 280 | 430 | 75 | 19 X 10 | 671 | |

| 1110 | 1050 | 150 | 300 | 450 | 75 | 19 X 10 | 794 | |

| 1270 | 1220 | 150 | 300 | 450 | 75 | 19 X 10 | 907 | |

| 1420 | 1370 | 175 | 300 | 480 | 75 | 19 X 10 | 1037 | |

| 1570 | 1520 | 175 | 300 | 480 | 75 | 19 X 10 | 1175 | |

| 600 | 400 | 350 | 125 | 230 | 350 | 75 | 19 X 10 | 342 |

| 450 | 400 | 125 | 230 | 350 | 75 | 19 X 10 | 362 | |

| 500 | 450 | 125 | 250 | 380 | 75 | 19 X 10 | 369 | |

| 550 | 500 | 125 | 250 | 380 | 75 | 19 X 10 | 432 | |

| 660 | 600 | 125 | 280 | 400 | 75 | 19 X 10 | 527 | |

| 810 | 750 | 150 | 330 | 480 | 85 | 22 X 11 | 693 | |

| 960 | 900 | 150 | 330 | 480 | 85 | 22 X 11 | 815 | |

| 1110 | 1050 | 175 | 350 | 530 | 100 | 25 X 12.5 | 929 | |

| 1270 | 1220 | 175 | 350 | 530 | 100 | 25 X 12.5 | 1040 | |

| 1420 | 1370 | 200 | 380 | 580 | 100 | 25 X 12.5 | 1217 | |

| 1570 | 1520 | 200 | 400 | 600 | 100 | 25 X 12.5 | 1357 | |

| 750 | 500 | 450 | 125 | 350 | 500 | 100 | 25 X 12.5 | 677 |

| 550 | 500 | 125 | 350 | 530 | 100 | 25 X 12.5 | 711 | |

| 660 | 600 | 125 | 350 | 530 | 100 | 25 X 12.5 | 855 | |

| 810 | 750 | 150 | 400 | 580 | 110 | 25 X 12.5 | 1085 | |

| 960 | 900 | 150 | 400 | 580 | 110 | 25 X 12.5 | 1278 | |

| 1110 | 1050 | 175 | 450 | 630 | 125 | 32 X 16 | 1530 | |

| 1270 | 1220 | 175 | 450 | 630 | 125 | 32 X 16 | 1737 | |

| 1420 | 1370 | 230 | 500 | 760 | 140 | 32 X 16 | 1937 | |

| 1570 | 1520 | 230 | 480 | 730 | 140 | 32 X 16 | 2167 | |

| 900 | 500 | 450 | 150 | 300 | 450 | 100 | 25 X 12.5 | 997 |

| 550 | 500 | 150 | 300 | 450 | 100 | 25 X 12.5 | 1040 | |

| 660 | 600 | 175 | 300 | 530 | 110 | 25 X 12.5 | 1217 | |

| 810 | 750 | 175 | 300 | 530 | 110 | 25 X 12.5 | 1494 | |

| 960 | 900 | 200 | 350 | 560 | 125 | 32 X 16 | 1814 | |

| 1110 | 1050 | 200 | 350 | 560 | 125 | 32 X 16 | 2093 | |

| 1270 | 1220 | 230 | 380 | 660 | 140 | 32 X 16 | 2408 | |

| 1420 | 1370 | 280 | 380 | 710 | 150 | 38 X 19 | 2723 | |

| 1570 | 1520 | 330 | 430 | 810 | 175 | 38 X 19 | 2993 |

We take this opportunity to introduce ourselves as one of the leading manufacturers of Magnetic equipment and magnetic pulley. With our wide product range for segregating ferrous substances the magnetic pulley comes in handy and can be installed to improve efficiency as well as to single handedly make separation. The pulley has a 360 degree magnet inside a metallic drum on which is a conveyer that brings the separation material. Magnetically active material are taken with the conveyer and discharges in a separate chamber while the others are dropped below the conveyer.

Advantages of Magnetic pulley are:

Magnetic pulleys are available in many sizes and strengths, if oversized magnetic pulleys are required they can be custom made in accordance with the place of mounting. Success lies in attaining the desired output. Consult our expert engineers to discuss on specifications.

Star Trace is one of the eminent companies known for their quality, trust and durable magnetic equipment. The Magnetic Head Pulley is a broadly used magnetic separation device capable of being set up in reasonable space. Having the capacity to handle huge volumes of input, the magnetic head pulley has robust construction. When the feed comes into contact with the magnetic head pulley ferrous substances are attracted and stay grooved to the pulley till they are relieved of the magnet’s intensity and fall into separate dispensing chamber.

Applications:To be very simple in describing its use, the magnetic head pulley is the basic equipment to isolate ferrous substances.

Having been in the field of magnets for more than twenty five years we owe our achievements to our dedicated engineers and loyal customers.

We, Star Trace Solutions Pvt. Ltd. having based ourselves as manufacturers and suppliers of magnetic equipment for mineral beneficiation have been serving the demands of small, medium and large companies globally. The permanent magnetic pulley is one of the modest equipment used to sort ferrous and nonferrous substances in an input.

It features a non-magnetic pulley shell concealing a permanent magnet to the fullest circumference. The driving force is from a motor with conveyor belt.

Materials crossing the magnetic field will be subject to attraction if magnetic and dispersed in a chamber, otherwise they fall freely right below the pulley.

Permanent magnets have the advantage of being maintenance free when compared to electro magnets for the simple reason of having no accessories.

Permanent magnetic Pulleys are used in

Permanent Magnetic Pulley is available in a series of dimensions, if nonstandard sizes are required customization is possible. Approach us and we will do the needful.

To live up to the specific requirements of our clients we at Star Trace have always been in the approach of reinventing our equipment with the latest technology. One among them is the Conveyor Magnetic Pulley.

From the name given; the Conveyor Magnetic Pulley consist of a conveyor which carries the raw material for ferrous separation to the magnetic pulley. On entering the strong magnetic field of the permanent magnet lodged inside the pulley all particles responding to the magnetic field are conveyed to a separate chamber and the rest drop down.

Features of Conveyor magnetic pulley are:

Check out our conveyor magnetic pulley available in diverse sizes and expect uninterrupted work flow.

The easiest and elementary way of separating ferrous from nonferrous substance is touse a Pulley Magnet. Star Trace offers permanent pulley magnets in different sizes to serve clients in diverse industries. We have been involved in manufacturing magnetic equipment for more than 25 years and are well aware of the nuances in the field which you can take advantage of as our privileged customer. The pulley magnet has a permanent magnet fitted in the pulley structure that is rotated with the help of a motor and conveyor belt arrangement. The belt brings the feed into magnetic field of the pulley magnet and the rest happens on its own. Ferrous matter is attracted by the magnet and discharged into a separate collection area. Non Ferrous substances drop down right below the pulley magnet.

Operating Areas:We being a dominant manufacturing company for magnetic equipment provide an assortment of Magnetic Drum Pulleys utilizing high quality components and modern technology as per the market standards. Magnetic Drum Pulley are designed to separate particles having iron properties from the non-irony ones using the permanent magnet.

Separation material is brought into contact with magnetic drum through a conveyor which in turn attracts ferrous particles and dislodges them separately. Magnetic Drum Pulley are:

With a wide area of applications the magnetic drum pulley is available in varying dimensions. Strict quality norms are followed for all our equipment and makes sure they are durable in any kind of working environment. Experience our superiority and you are sure to get the best out of all out equipment.